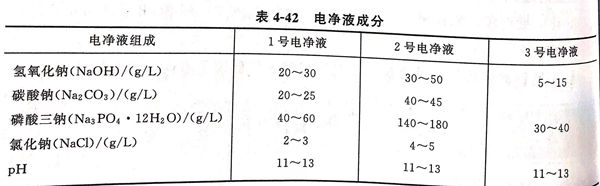

1. 電凈(jing)液(ye)成分見表4-42.

2. 電凈液的性質和用途

電(dian)凈液(ye)都是堿性溶液(ye),pH為11~13.溶液(ye)呈無(wu)色(se)透明,手摸有滑感,-10℃不(bu)結冰。

電(dian)凈液具有較強的(de)去油作(zuo)用,同時具有輕(qing)度的(de)除氧(yang)化膜作(zuo)用。

3. 使用(yong)方(fang)法

用鍍筆(bi)蘸上(shang)(shang)電(dian)(dian)凈液,大型圓柱(zhu)形(xing)工(gong)(gong)件夾在(zai)(zai)機床車頭上(shang)(shang)旋轉,鍍筆(bi)固定(ding)在(zai)(zai)刀架(jia)上(shang)(shang)不(bu)動,將鍍筆(bi)和工(gong)(gong)件接觸(chu),并保持一定(ding)的相(xiang)對運動速率,如(ru)果是平面(mian)工(gong)(gong)件,則工(gong)(gong)件固定(ding),鍍筆(bi)在(zai)(zai)工(gong)(gong)件平面(mian)上(shang)(shang)接觸(chu),用手工(gong)(gong)移動保持相(xiang)對運動速率。在(zai)(zai)通電(dian)(dian)的情況下在(zai)(zai)工(gong)(gong)件表面(mian)涂(tu)抹,達到(dao)去(qu)油的目的。

工件(jian)(jian)(jian)與鍍筆之間的通電(dian)有兩種(zhong)(zhong)方式:一種(zhong)(zhong)稱(cheng)為正(zheng)極(ji)性電(dian)凈(jing)(jing),工件(jian)(jian)(jian)接負極(ji),鍍筆接正(zheng)極(ji),去(qu)(qu)油效果(guo)快捷。通電(dian)時(shi)工件(jian)(jian)(jian)表面產生大量的氫(qing)氣,故工件(jian)(jian)(jian)有滲(shen)氫(qing)現(xian)象;另一種(zhong)(zhong)稱(cheng)為反極(ji)性電(dian)凈(jing)(jing),工件(jian)(jian)(jian)接正(zheng)極(ji),鍍筆接負極(ji),通電(dian)時(shi)工件(jian)(jian)(jian)表面產生氧氣,其去(qu)(qu)油效果(guo)中(zhong)等,作(zuo)用溫和,沒有滲(shen)氫(qing)現(xian)象。在實(shi)際工作(zuo)中(zhong),往往是采用高檔(dang)電(dian)壓(10~18V),先正(zheng)極(ji)性電(dian)凈(jing)(jing)后反極(ji)性電(dian)凈(jing)(jing)聯合應用,效果(guo)最(zui)佳。

4. 電凈工藝條件(jian)

電壓10~18V,一般(ban)取12V;時間(jian)30~90s;電凈液溫度 15~50℃。

電凈后立即用水沖(chong)洗干凈,表面(mian)水膜(mo)分布(bu)均勻,金屬表面(mian)呈現均勻的潔(jie)凈狀(zhuang)態,立即進行下道工序(xu),不可使表面(mian)形成干斑。