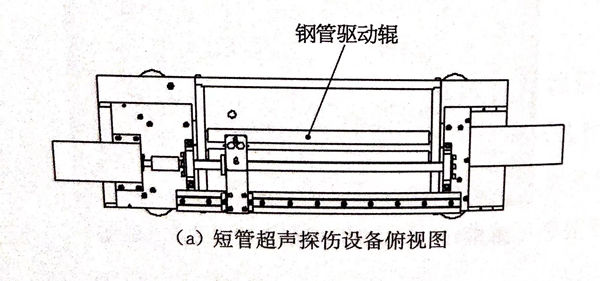

不銹鋼長管經過探傷后進入后續工序,加工成短管,成品管在交付前還需要最終超聲波探傷。通常情況下,成品管的長度不超過1.5m,此時對不銹(xiu)鋼管的表面質量要求很高,大型的探傷設備顯然不適用。最適宜的超聲探傷方法應該采用鋼管旋轉,超聲探頭直線移動。不銹鋼短管超聲半自動探傷設備如圖5.14所示。

不銹鋼(gang)(gang)短(duan)管(guan)(guan)置于水(shui)(shui)槽(cao)中,采(cai)用(yong)雙輥(gun)驅動(dong)(dong)(dong)(dong)(dong)方式,利用(yong)摩擦(ca)力帶動(dong)(dong)(dong)(dong)(dong)鋼(gang)(gang)管(guan)(guan)高(gao)速(su)旋轉(zhuan)。為(wei)增加摩擦(ca)系數,雙輥(gun)表面(mian)包(bao)覆橡膠。雙輥(gun)轉(zhuan)動(dong)(dong)(dong)(dong)(dong)、探(tan)(tan)頭(tou)移動(dong)(dong)(dong)(dong)(dong)分別采(cai)用(yong)伺(si)服系統(tong)作(zuo)(zuo)為(wei)原動(dong)(dong)(dong)(dong)(dong)機,探(tan)(tan)頭(tou)移動(dong)(dong)(dong)(dong)(dong)通過滾珠絲杠(gang)配合直線(xian)導軌實現(xian)。協調好不銹鋼(gang)(gang)短(duan)管(guan)(guan)的旋轉(zhuan)速(su)度(du)及探(tan)(tan)頭(tou)移動(dong)(dong)(dong)(dong)(dong)速(su)度(du),探(tan)(tan)傷(shang)(shang)螺距(ju)不超(chao)過探(tan)(tan)頭(tou)有效探(tan)(tan)傷(shang)(shang)面(mian)積的80%,滿足短(duan)管(guan)(guan)全長度(du)檢測,端部(bu)不存在盲區。不銹鋼(gang)(gang)短(duan)管(guan)(guan)屬于成(cheng)品管(guan)(guan),鋼(gang)(gang)管(guan)(guan)表面(mian)光潔無(wu)附著物(wu),因此探(tan)(tan)傷(shang)(shang)設(she)備耦合水(shui)(shui)可(ke)以不采(cai)用(yong)循環水(shui)(shui),水(shui)(shui)槽(cao)內的水(shui)(shui)每(mei)天更換一次即可(ke)。探(tan)(tan)傷(shang)(shang)時,操作(zuo)(zuo)人員手動(dong)(dong)(dong)(dong)(dong)將短(duan)管(guan)(guan)放入水(shui)(shui)槽(cao)內,雙輥(gun)驅動(dong)(dong)(dong)(dong)(dong)鋼(gang)(gang)管(guan)(guan)高(gao)速(su)旋轉(zhuan),探(tan)(tan)頭(tou)直線(xian)移動(dong)(dong)(dong)(dong)(dong),檢測起始與結束位(wei)置交(jiao)替變化(hua),探(tan)(tan)傷(shang)(shang)完成(cheng)后手動(dong)(dong)(dong)(dong)(dong)取出。