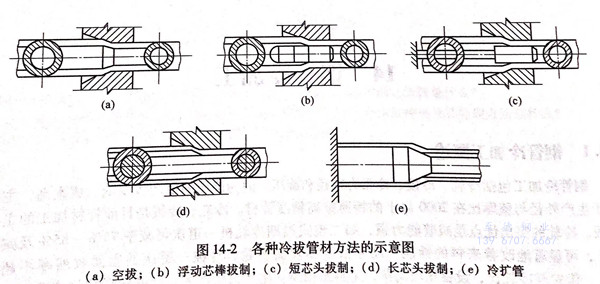

冷拔可以生產直徑0.2~765mm,壁厚0.015~50mm的不銹鋼(gang)管,是毛細管、小直徑厚壁管以及部分異形管的主要生產方式,目前直線運動冷拔機的最大拔制長度已達50m.圖14-2所示為現有冷拔不(bu)銹鋼管材的主要方法。

1. 無(wu)芯頭拔制(空(kong)拔圖14-2 圖 a)

它(ta)是管(guan)(guan)料(liao)通過拔管(guan)(guan)模進行空心(xin)壓縮(suo),直徑減(jian)小,壁厚(hou)卻有所增加,其增加量隨鋼管(guan)(guan)尺寸(cun)而異。它(ta)用于(yu)減(jian)徑、定(ding)徑,每道最大延伸系數1.5,這主要受(shou)變(bian)形(xing)(xing)區(qu)內橫斷面(mian)上(shang)不均勻(yun)變(bian)形(xing)(xing)和材料(liao)本身強度的(de)限制(zhi)。對(dui)薄壁管(guan)(guan)還需考慮變(bian)形(xing)(xing)區(qu)內管(guan)(guan)體橫斷面(mian)形(xing)(xing)狀穩定(ding)性的(de)限制(zhi),所以無芯頭(tou)拔制(zhi)時壁厚(hou)與外(wai)徑比不得小于(yu)0.04。

2. 浮動(dong)芯頭(tou)拔制(圖14-2(b))

它主要(yao)用(yong)于生產(chan)小(xiao)徑(jing)長不(bu)銹鋼(gang)管(guan)(guan)(guan)(guan)(guan),每道延(yan)伸系數(shu)1.2~1.8。它與上述空拔(ba)都是毛細(xi)管(guan)(guan)(guan)(guan)(guan)、小(xiao)徑(jing)厚(hou)壁(bi)管(guan)(guan)(guan)(guan)(guan)生產(chan)的(de)(de)主要(yao)方法(fa),它們都便于采用(yong)卷(juan)(juan)筒(tong)(tong)(tong)拔(ba)制(zhi)(zhi),卷(juan)(juan)筒(tong)(tong)(tong)拔(ba)制(zhi)(zhi)的(de)(de)最(zui)(zui)大管(guan)(guan)(guan)(guan)(guan)徑(jing),鋼(gang)管(guan)(guan)(guan)(guan)(guan)36mm,銅(tong)(tong)管(guan)(guan)(guan)(guan)(guan)60mm;最(zui)(zui)大拔(ba)制(zhi)(zhi)速度,鋼(gang)管(guan)(guan)(guan)(guan)(guan)達(da)到300m/min,銅(tong)(tong)管(guan)(guan)(guan)(guan)(guan)達(da)到720m/min,拔(ba)制(zhi)(zhi)長度在(zai)130~2300m;卷(juan)(juan)筒(tong)(tong)(tong)直徑(jing)視拔(ba)制(zhi)(zhi)的(de)(de)管(guan)(guan)(guan)(guan)(guan)徑(jing)和壁(bi)厚(hou)而(er)定(ding),管(guan)(guan)(guan)(guan)(guan)徑(jing)愈(yu)大管(guan)(guan)(guan)(guan)(guan)壁(bi)愈(yu)薄,卷(juan)(juan)筒(tong)(tong)(tong)直徑(jing)應(ying)(ying)愈(yu)大,目前(qian)最(zui)(zui)大卷(juan)(juan)筒(tong)(tong)(tong)直徑(jing)已達(da)3150mm.確定(ding)延(yan)伸系數(shu)時應(ying)(ying)注意,卷(juan)(juan)筒(tong)(tong)(tong)拔(ba)制(zhi)(zhi)要(yao)比(bi)直線拔(ba)制(zhi)(zhi)小(xiao)15%~20%。

3. 短(duan)芯頭拔制(圖14-2(c))

是將不(bu)銹鋼管(guan)(guan)(guan)(guan)料拉過拔管(guan)(guan)(guan)(guan)模,使其在模孔與固定的(de)頂(ding)頭所組(zu)成的(de)環形孔型中獲得減(jian)徑和減(jian)壁。這種拔制方法應(ying)用較(jiao)廣,一道的(de)最大延伸系數1.7左右。主要(yao)受到被拔管(guan)(guan)(guan)(guan)體強度的(de)限制,小直徑管(guan)(guan)(guan)(guan)有時受到芯桿強度的(de)限制。

4. 長芯棒拔(ba)制(zhi)(圖14-2(d))

是(shi)將不(bu)銹鋼管料套于長芯棒(bang)(bang)(bang)上(shang),然后同(tong)長芯棒(bang)(bang)(bang)一(yi)起拉過(guo)拔管模,不(bu)銹鋼管在芯棒(bang)(bang)(bang)與(yu)模孔(kong)所組成的(de)(de)環狀孔(kong)型(xing)中(zhong)獲得(de)減徑和壁厚壓(ya)縮(suo)。這種拔制方法(fa)的(de)(de)減壁能力強(qiang),可獲得(de)幾何尺(chi)寸(cun)精度(du)較高,表(biao)面質(zhi)量較好的(de)(de)管材。小(xiao)(xiao)直徑薄壁管(外徑小(xiao)(xiao)于3.0mm,壁厚小(xiao)(xiao)于0.2mm)目(mu)前(qian)只有用此法(fa)生產(chan)。此法(fa)一(yi)道(dao)次的(de)(de)最大延伸系數為2.0~2.2.為取(qu)消脫棒(bang)(bang)(bang)工序,現已研(yan)究出了冷拔和脫棒(bang)(bang)(bang)合(he)并進行的(de)(de)方法(fa),如冷拔的(de)(de)同(tong)時輾軋管壁,拔后便(bian)可自行脫棒(bang)(bang)(bang)。

5. 冷擴管(guan)(圖14-2(e))

冷擴管方法主要用于生產大直徑薄壁不銹(xiu)鋼(gang)管(guan),進行管材內徑的定徑,制造雙金屬管等。一般不銹鋼管擴徑量為15%~20%。

冷(leng)拔(ba)不銹(xiu)鋼管的生(sheng)產特(te)點為(wei):每道(dao)(dao)次(ci)變形(xing)量較(jiao)小(xiao),一般(ban)壓縮率小(xiao)于40%,壁(bi)厚(hou)的壓縮較(jiao)小(xiao),多道(dao)(dao)次(ci)循環性生(sheng)產。一般(ban)的工(gong)(gong)藝過(guo)程如圖14-1所示,這(zhe)種生(sheng)產方法,生(sheng)產靈活性大、尺寸精確、表(biao)面(mian)質量高及力學性能好、設備結(jie)構與(yu)工(gong)(gong)具簡單、調整(zheng)方便、制造容易、造價低,但工(gong)(gong)序多、生(sheng)產周期長、消耗大,受金屬強度(du)限(xian)制,一般(ban)不能冷(leng)拔(ba)直(zhi)徑(jing)與(yu)壁(bi)厚(hou)之比(D/S)大于100的薄壁(bi)鋼管。

不銹鋼(gang)管(guan)材(cai)冷拔(ba)目前發(fa)展的總趨勢是多(duo)條、快速、長行程和拔(ba)制(zhi)(zhi)(zhi)操作連(lian)(lian)續化。如(ru)曼(man)乃斯曼(man)-米爾公司(si)制(zhi)(zhi)(zhi)造的鏈式高速、多(duo)線冷拔(ba)管(guan)機,拔(ba)制(zhi)(zhi)(zhi)速度(du)達到120m/min,同(tong)時可(ke)拔(ba)五根,最大拔(ba)制(zhi)(zhi)(zhi)長度(du)60m。該廠(chang)生產(chan)的履帶(dai)式冷拔(ba)機可(ke)以連(lian)(lian)續拔(ba)制(zhi)(zhi)(zhi),最大拔(ba)制(zhi)(zhi)(zhi)速度(du)為100~300m/min。