家用電器不銹鋼(gang)化的首要問題就是可能會增加成本。即便如此,全自動不銹鋼桶洗衣機、滾筒式洗滌干燥機由于其清潔性,耐用性銷售量爆發式大增,繼而家用電器全部不銹鋼化,就連衣類干燥機也由表面處理鋼板改為不銹鋼。

1. 洗衣(yi)機

無論何種洗衣機都是要和水接觸,因此大多數洗衣機都是先用不銹鋼的代表鋼種06Cr19Ni10(304)。也可以選用0022Cr18Ti(439)、019Cr17MoNb(436L)等可進行深度拉深的鋼種,可作為洗衣機的首選鋼種。它在制造洗衣機洗滌桶時,無論是采用焊接結構或是鉚接結構,均可以確保有足夠的耐腐蝕性能。

洗(xi)衣(yi)機(ji)加(jia)工(gong)(gong)(gong)時(shi)使用(yong)(yong)(yong)厚(hou)度0.5mm或0.6mm的不(bu)銹鋼(gang)薄(bo)板,采(cai)用(yong)(yong)(yong)焊接(jie)(jie)(jie)方(fang)(fang)法(fa)或是鉚接(jie)(jie)(jie)方(fang)(fang)法(fa)制造。洗(xi)滌桶(tong)的中間(jian)桶(tong)體可(ke)(ke)以(yi)采(cai)用(yong)(yong)(yong)不(bu)銹鋼(gang)卷(juan)材或板材采(cai)用(yong)(yong)(yong)壓(ya)沖(chong)(chong)工(gong)(gong)(gong)藝(yi)進(jin)行(xing)(xing)連續加(jia)工(gong)(gong)(gong)業。為脫水(shui)而(er)(er)設置許(xu)多小孔(kong),使用(yong)(yong)(yong)沖(chong)(chong)床(chuang)的沖(chong)(chong)頭(凸(tu)模(mo))進(jin)行(xing)(xing)沖(chong)(chong)孔(kong),為了使洗(xi)滌物不(bu)被劃傷,要(yao)施行(xing)(xing)去(qu)毛刺(ci)(ci)工(gong)(gong)(gong)序,將所有(you)沖(chong)(chong)孔(kong)的毛刺(ci)(ci)、銳(rui)(rui)邊、尖(jian)角(jiao)去(qu)除,然后(hou)壓(ya)制出像洗(xi)衣(yi)板樣的凸(tu)點(dian),接(jie)(jie)(jie)著進(jin)行(xing)(xing)桶(tong)體卷(juan)圓成(cheng)形(xing)(xing)。對接(jie)(jie)(jie)部分采(cai)用(yong)(yong)(yong)TIG焊接(jie)(jie)(jie)方(fang)(fang)式(shi)和鉚接(jie)(jie)(jie)方(fang)(fang)式(shi)進(jin)行(xing)(xing)連接(jie)(jie)(jie)。然后(hou),桶(tong)腹部的上沿其(qi)邊緣要(yao)進(jin)行(xing)(xing)卷(juan)邊,使其(qi)形(xing)(xing)成(cheng)圓形(xing)(xing)邊緣。下部分則要(yao)和不(bu)銹鋼(gang)桶(tong)底相接(jie)(jie)(jie)合(he)。不(bu)銹鋼(gang)桶(tong)底,采(cai)用(yong)(yong)(yong)鉚接(jie)(jie)(jie)方(fang)(fang)式(shi)較(jiao)多。鉚接(jie)(jie)(jie)方(fang)(fang)式(shi)有(you)如上所述幾(ji)種加(jia)工(gong)(gong)(gong)工(gong)(gong)(gong)序,為了防止產生毛刺(ci)(ci)、銳(rui)(rui)角(jiao)或尖(jian)邊,加(jia)工(gong)(gong)(gong)時(shi)需要(yao)潤滑,大多數是采(cai)用(yong)(yong)(yong)在(zai)不(bu)銹鋼(gang)薄(bo)板上貼附表(biao)面(mian)保護薄(bo)膜的狀態下,進(jin)行(xing)(xing)加(jia)工(gong)(gong)(gong)。但是,如采(cai)用(yong)(yong)(yong)TIG焊接(jie)(jie)(jie)方(fang)(fang)式(shi),因(yin)表(biao)面(mian)保護薄(bo)膜而(er)(er)不(bu)利于焊接(jie)(jie)(jie),可(ke)(ke)改用(yong)(yong)(yong)在(zai)焊接(jie)(jie)(jie)過程(cheng)中自行(xing)(xing)揮(hui)發狀態的揮(hui)發性(xing)加(jia)工(gong)(gong)(gong)油,以(yi)實現連續性(xing)批量生產。采(cai)用(yong)(yong)(yong)TIG焊接(jie)(jie)(jie)方(fang)(fang)式(shi)的焊接(jie)(jie)(jie)速度是產量和生產成(cheng)本的關鍵工(gong)(gong)(gong)序。

滾筒(tong)式洗滌干(gan)燥機,由于具有干(gan)燥功能,要(yao)進行加(jia)(jia)熱干(gan)燥,所(suo)以(yi)必須使用(yong)不(bu)銹鋼(gang)桶(tong)。因(yin)不(bu)銹鋼(gang)桶(tong)是(shi)雙(shuang)層結構,所(suo)以(yi)一(yi)臺不(bu)銹鋼(gang)用(yong)量(liang)相當于原來的2臺以(yi)上。在選(xuan)定材料和加(jia)(jia)工方(fang)法方(fang)面,基(ji)本上和上述(shu)全自(zi)動(dong)洗滌機類似(si)。

2. 電熱水器(qi)

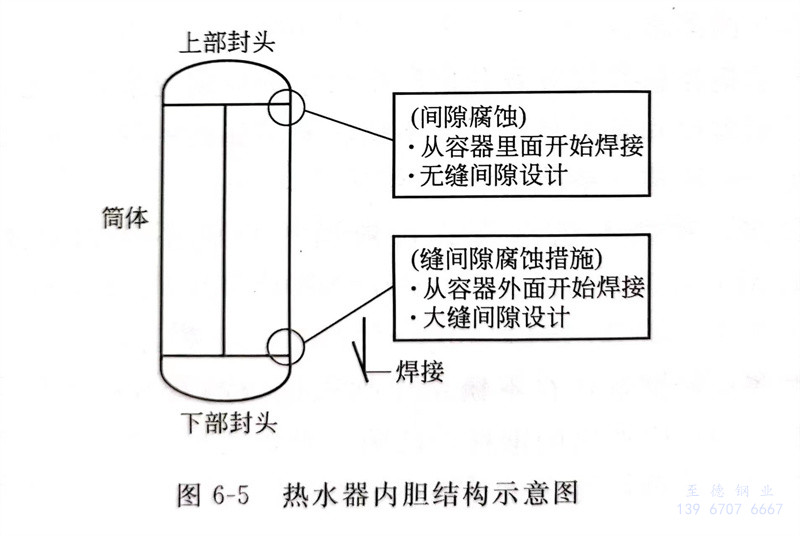

制作不銹(xiu)鋼熱水罐(guan)曾沿用(yong)06Cr19Ni10(304),但(dan)多次發生應力腐蝕開裂(lie)問題(ti)。鐵素體系列(lie)不銹(xiu)鋼019Cr19Mo2NbTi(444),對(dui)防止(zhi)應力腐蝕開裂(lie)是一種完美(mei)對(dui)策。雖然使用(yong)鐵素體系列(lie)不銹(xiu)鋼,但(dan)熱水罐(guan)上下封頭與筒(tong)體接合處仍有(you)零星(xing)間隙腐蝕發生,加強焊接質量及接合部(bu)間隙的管理(li)問題(ti)即可解決。

裝(zhuang)(zhuang)配間隙過于狹窄是造(zao)成間隙腐蝕的原(yuan)因(yin)。所以(yi)有必要適當加大(da)裝(zhuang)(zhuang)配間隙。對回收的舊電熱水(shui)器熱水(shui)罐內(nei)部(bu)(bu)進行(xing)調查,由于使用了019Cr19Mo2NbTi(444)而使熱水(shui)罐內(nei)部(bu)(bu)幾乎沒(mei)有腐蝕,質(zhi)量事故多使其他零部(bu)(bu)件損壞而不能(neng)使用。可以(yi)說(shuo),電熱水(shui)器筒體的不銹鋼(gang)化,是“機能(neng)材料選定”最適合的產品(pin)。

加工方面:上、下封頭使用厚度為1.0~1.2mm的(de)不銹鋼薄板(ban),沖壓而成。筒體(ti)選用0.6~0.8mm的(de)不銹鋼薄板(ban),采用TIG焊接(jie)(jie)。考慮到熱水器(qi)上部(bu)因水位高低的(de)變化,使得氣相和液相在(zai)上部(bu)反復交替變化,進而氯離(li)子(zi)濃度在(zai)逐漸變濃,易產(chan)生腐蝕(shi),所(suo)以上部(bu)的(de)焊縫應從內部(bu)焊接(jie)(jie)。

圖(tu)6-5是熱水器內結構膽示意圖(tu)及可能出現腐蝕。

熱水器內膽加工(gong)(gong)(gong)工(gong)(gong)(gong)藝流程:下料→沖(chong)壓封頭→加工(gong)(gong)(gong)出入水孔→卷筒(tong)→焊接筒(tong)體→焊接上(shang)下封頭→耐(nai)壓檢(jian)驗。