①. 對于(yu)使用(yong)電動機超過200kW(2000kg)的大型泵,當檢查維修時(shi)不能(neng)使用(yong)叉車(che)或(huo)吊車(che)時(shi),如管(guan)廊下、管(guan)廊和(he)設備(bei)之間(jian)等,應(ying)設置(zhi)吊梁(載(zai)重滑車(che)梁)。設置(zhi)時(shi)應(ying)充分考慮泵殼、葉輪軸的拆卸以及用(yong)于(yu)外(wai)抽時(shi)的吊梁。

②. 原(yuan)則(ze)上每(mei)臺(tai)泵(beng)都設一根吊梁,但(dan)是如果起吊區無空間,亦可兼用一根。

③. 設置在管(guan)(guan)(guan)廊下的泵(beng),其(qi)吊梁高度(du)應(ying)不影響出(chu)入管(guan)(guan)(guan)廊的配(pei)管(guan)(guan)(guan)、儀表(biao)電氣管(guan)(guan)(guan)纜及照明用支架懸臂。

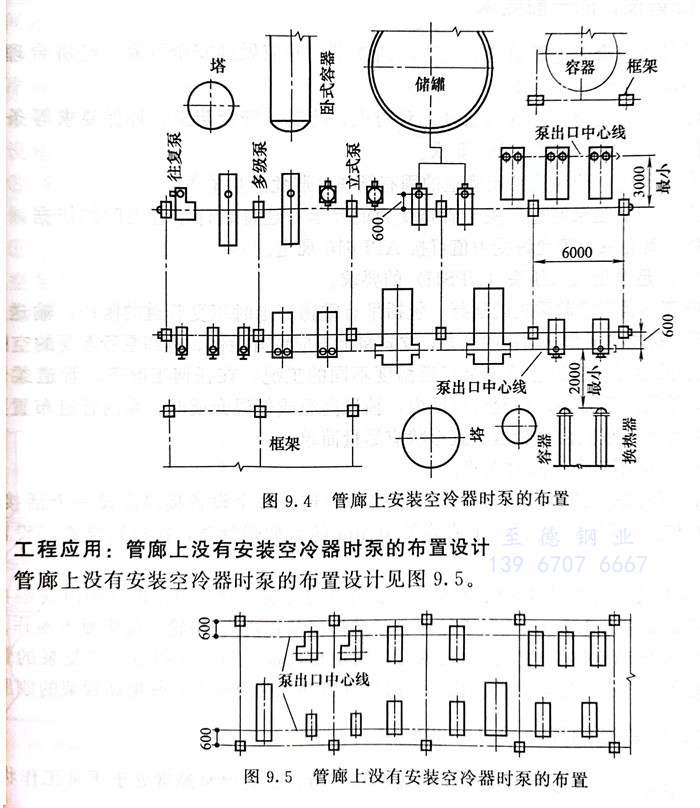

工程應用:管(guan)廊上安裝空冷(leng)器時泵的布置

見圖9.4,在(zai)管(guan)(guan)(guan)(guan)廊(lang)下(xia)6m一跨之內,可布置大型(xing)泵(beng)(beng)1臺、中(zhong)型(xing)泵(beng)(beng)2臺、小(xiao)(xiao)型(xing)泵(beng)(beng)3臺,一般泵(beng)(beng)單排布置,出口中(zhong)心(xin)線(xian)(xian)對齊,距(ju)管(guan)(guan)(guan)(guan)廊(lang)柱(zhu)中(zhong)心(xin)線(xian)(xian)的間距(ju)在(zai)600~2000mm之間。在(zai)管(guan)(guan)(guan)(guan)廊(lang)上方有(you)(you)空冷器時,如(ru)泵(beng)(beng)的操(cao)作溫度(du)(du)(du)在(zai)340℃以(yi)下(xia)則(ze)泵(beng)(beng)布置在(zai)管(guan)(guan)(guan)(guan)廊(lang)外側(ce)(ce)(ce),泵(beng)(beng)出口中(zhong)心(xin)線(xian)(xian)對齊,伸出管(guan)(guan)(guan)(guan)廊(lang)距(ju)柱(zhu)中(zhong)心(xin)線(xian)(xian)0.6m。泵(beng)(beng)的驅(qu)動機在(zai)管(guan)(guan)(guan)(guan)廊(lang)內側(ce)(ce)(ce)。如(ru)泵(beng)(beng)的操(cao)作溫度(du)(du)(du)等于或(huo)大于340℃時,則(ze)泵(beng)(beng)布置在(zai)管(guan)(guan)(guan)(guan)廊(lang)外側(ce)(ce)(ce),泵(beng)(beng)出口中(zhong)心(xin)線(xian)(xian)對齊,距(ju)管(guan)(guan)(guan)(guan)廊(lang)柱(zhu)中(zhong)心(xin)線(xian)(xian)3m。泵(beng)(beng)的驅(qu)動機也(ye)在(zai)管(guan)(guan)(guan)(guan)廊(lang)外側(ce)(ce)(ce)。泵(beng)(beng)前方的操(cao)作檢修通(tong)(tong)道,可能有(you)(you)小(xiao)(xiao)型(xing)叉車通(tong)(tong)行,其寬度(du)(du)(du)不(bu)小(xiao)(xiao)于1250mm,在(zai)多級泵(beng)(beng)前方的寬度(du)(du)(du)不(bu)小(xiao)(xiao)于1800mm。兩排泵(beng)(beng)之間的檢修通(tong)(tong)道,寬度(du)(du)(du)不(bu)小(xiao)(xiao)于3000mm,如(ru)不(bu)夠時,泵(beng)(beng)端應有(you)(you)3000mm的通(tong)(tong)道。

工(gong)程應用:管廊上沒有安裝空冷(leng)器時泵的布置(zhi)設計

管廊上(shang)沒(mei)有安裝空(kong)冷器時(shi)泵的布置(zhi)設計見圖 9.5

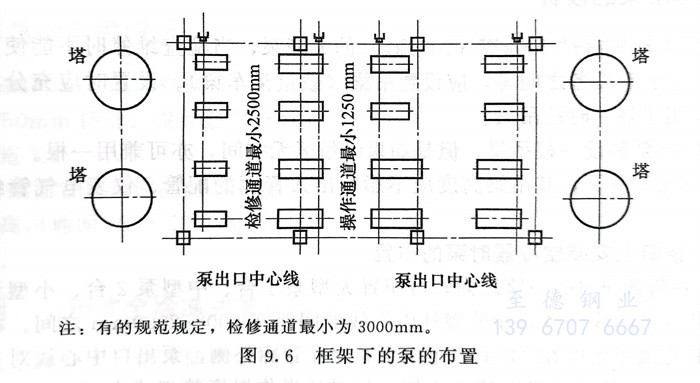

工程應(ying)用:框架下的泵的布置設計

框架下的泵的布置設計見圖 9.6