埋弧焊時為了調整焊接機頭與不銹(xiu)鋼管焊件的相對位置,使整個焊接過程中待焊處始終處于最適合焊接的位置,還要保證在施焊過程中穩定、可靠安全,一般均需有相應的輔助設備與焊機相配合。輔助設備有焊接夾具、焊件變位設備、焊機機頭變位設備、焊縫成形設備和導電嘴等。

1. 焊接夾(jia)具

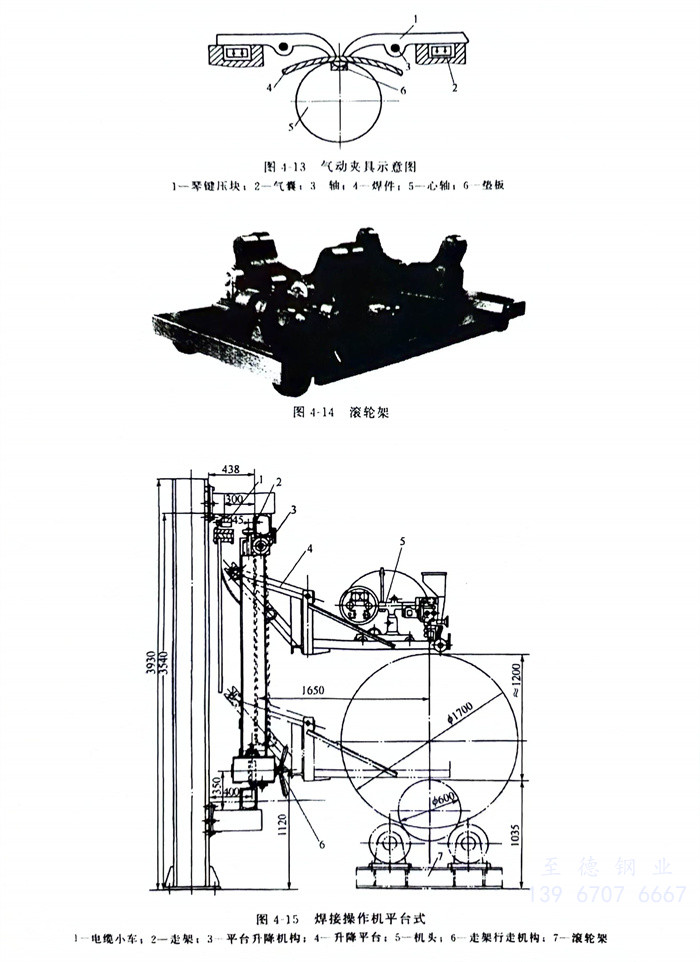

其目的在于使(shi)不銹鋼管焊(han)件(jian)準確定(ding)位并夾緊,以(yi)便焊(han)接。這(zhe)樣可(ke)以(yi)減(jian)少或(huo)免去定(ding)位焊(han)縫(feng)且能減(jian)少焊(han)接變形。圖(tu)4-13為(wei)一種(zhong)常用的筒(tong)形工件(jian)縱焊(han)縫(feng)的琴鍵夾具(ju)的示意圖(tu),配(pei)有成(cheng)形銅墊板,能獲得(de)單面(mian)焊(han)雙面(mian)成(cheng)形的焊(han)縫(feng)。

2. 焊件變位設備

主(zhu)要功能是使(shi)焊(han)(han)件(jian)(jian)旋轉(zhuan)(zhuan)、傾斜、翻轉(zhuan)(zhuan) 以使(shi)待(dai)焊(han)(han)處(chu)處(chu)于(yu)最適合焊(han)(han)接(jie)的位(wei)置,來達(da)到提高(gao)生產(chan)效率,保(bao)證焊(han)(han)縫質(zhi)量(liang)和(he)減輕工人勞動強(qiang)度的目的。焊(han)(han)件(jian)(jian)變位(wei)設備的形(xing)(xing)式、結(jie)構(gou)和(he)尺寸要根據(ju)焊(han)(han)接(jie)構(gou)件(jian)(jian)的形(xing)(xing)式、重量(liang)專門設計(ji)。通(tong)常有滾(gun)輪(lun)架(jia)(jia)和(he)翻轉(zhuan)(zhuan)機等。用(yong)(yong)于(yu)回轉(zhuan)(zhuan)體的典型滾(gun)輪(lun)架(jia)(jia)如(ru)圖(tu)4-14所示。長軸式焊(han)(han)接(jie)滾(gun)輪(lun)架(jia)(jia)的主(zhu)動滾(gun)輪(lun)與(yu)從動滾(gun)輪(lun)的數量(liang)較多時,要求滾(gun)輪(lun)始(shi)終保(bao)持在同一軸線上(shang),焊(han)(han)件(jian)(jian)在上(shang)面不易變形(xing)(xing)和(he)打滑。這種滾(gun)輪(lun)架(jia)(jia)適用(yong)(yong)于(yu)焊(han)(han)接(jie)中(zhong)、薄壁、長度大(da)的筒(tong)形(xing)(xing)焊(han)(han)件(jian)(jian)。筒(tong)體上(shang)如(ru)有凸出附(fu)件(jian)(jian),應防止轉(zhuan)(zhuan)動中(zhong)與(yu)長軸相互干涉(she)。

3. 焊機(ji)機(ji)頭(tou)變位設備

這種設備又稱焊(han)接(jie)操作(zuo)機。它能將(jiang)焊(han)接(jie)機頭對準待(dai)焊(han)位置(zhi),使之(zhi)在該位置(zhi)上操作(zuo),或者(zhe)以一定速度(du)沿(yan)規定軌跡移動焊(han)機機頭進行焊(han)接(jie)。它與(yu)焊(han)接(jie)滾(gun)(gun)輪(lun)架(滾(gun)(gun)輪(lun)架的結構形(xing)式(shi)(shi)(shi)(shi)、選用(yong)(yong),見(jian)JB/T 9187-1999《焊(han)接(jie)滾(gun)(gun)輪(lun)架》)等配合使用(yong)(yong),能完成各種構件的焊(han)接(jie)。其基本形(xing)式(shi)(shi)(shi)(shi)有平臺式(shi)(shi)(shi)(shi)、懸臂式(shi)(shi)(shi)(shi)、伸縮式(shi)(shi)(shi)(shi)、龍門式(shi)(shi)(shi)(shi)等幾(ji)種。常用(yong)(yong)的平臺焊(han)接(jie)操作(zuo)機與(yu)滾(gun)(gun)輪(lun)架配合使用(yong)(yong)情(qing)況(kuang),如圖4-14、圖4-15所示。

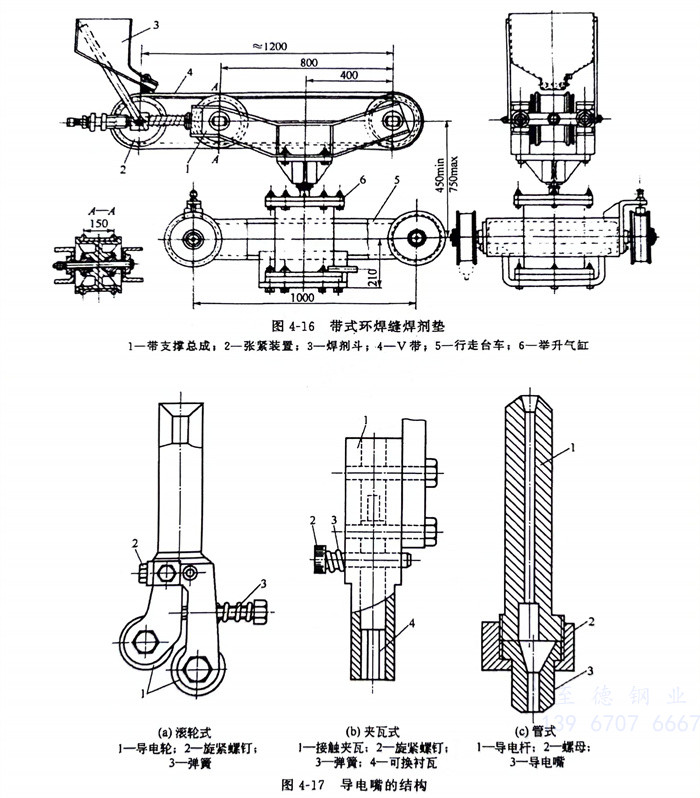

4. 焊縫(feng)成(cheng)形設(she)備

由(you)于埋弧焊(han)的(de)電(dian)弧功(gong)率較大,在(zai)(zai)對接(jie)接(jie)頭焊(han)接(jie)時(shi),為了防(fang)止熔(rong)化(hua)金屬的(de)流(liu)失和燒(shao)穿并促使焊(han)縫(feng)(feng)背面(mian)(mian)成形(xing),往(wang)往(wang)需要在(zai)(zai)焊(han)縫(feng)(feng)背面(mian)(mian)加墊(dian)板。最常用(yong)(yong)的(de)焊(han)縫(feng)(feng)成形(xing)設(she)備除前面(mian)(mian)所述的(de)銅墊(dian)板外,還有焊(han)劑襯墊(dian)。它適用(yong)(yong)于縱焊(han)縫(feng)(feng)和環(huan)焊(han)縫(feng)(feng)。圖(tu)(tu)4-16為典(dian)型的(de)帶(dai)式環(huan)焊(han)縫(feng)(feng)焊(han)劑墊(dian)的(de)示意圖(tu)(tu)。圖(tu)(tu)中舉升氣缸6在(zai)(zai)工作(zuo)時(shi)將(jiang)帶(dai)支撐總成1舉起,使帶(dai)兩邊凸棱(leng)與工作(zuo)表(biao)面(mian)(mian)接(jie)觸,帶(dai)在(zai)(zai)摩擦力的(de)作(zuo)用(yong)(yong)下(xia)隨焊(han)件運動。位于帶(dai)一端的(de)焊(han)劑斗3內的(de)焊(han)劑經出料口落在(zai)(zai)帶(dai)上,傳(chuan)到待(dai)焊(han)點(dian)的(de)下(xia)方,托住(zhu)高溫的(de)熔(rong)池(chi),過(guo)后將(jiang)多余焊(han)劑傳(chuan)到另一端,落入回收箱內,供重復使用(yong)(yong)(需篩除碎粉(fen)、渣殼等(deng),并重新烘(hong)干(gan))。

5. 導電(dian)嘴

導(dao)(dao)電(dian)(dian)嘴按結構分為管(guan)式(shi)導(dao)(dao)電(dian)(dian)嘴(或(huo)稱管(guan)狀偏(pian)心導(dao)(dao)電(dian)(dian)嘴、偏(pian)心導(dao)(dao)電(dian)(dian)嘴)、滾輪(lun)式(shi)(或(huo)稱滾動式(shi)導(dao)(dao)電(dian)(dian)嘴)、夾閘瓦(wa)式(shi)導(dao)(dao)電(dian)(dian)嘴(或(huo)瓦(wa)片式(shi)導(dao)(dao)電(dian)(dian)嘴)。Φ4.0mm以(yi)下的細焊絲(si)常用管(guan)式(shi)導(dao)(dao)電(dian)(dian)嘴;Φ4.0mm以(yi)上的焊絲(si)宜用滾輪(lun)式(shi)或(huo)夾瓦(wa)式(shi)導(dao)(dao)電(dian)(dian)嘴。導(dao)(dao)電(dian)(dian)嘴的結構見圖4-17。