焊接不銹鋼異徑管的一般要求有以下幾點:

①. 焊制異徑管的圓度不(bu)應大(da)于(yu)各端外徑的1%,且不(bu)大(da)于(yu)5mm.

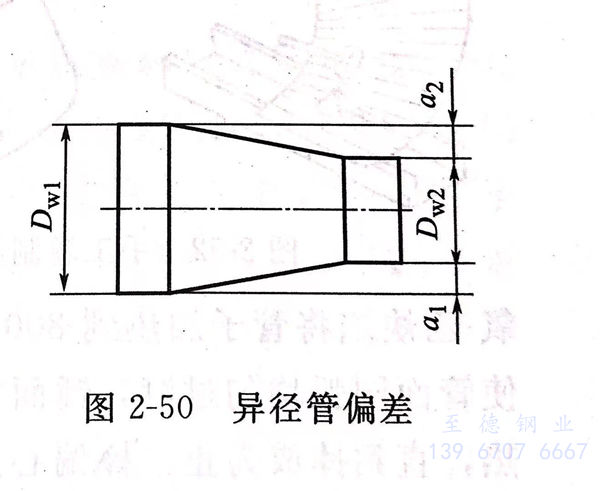

②. 同心(xin)異徑管兩端(duan)(duan)中心(xin)線(xian)應(ying)重合,其偏心(xin)值(a1-a2)/2(符號見圖2-50)不應(ying)大(da)于大(da)端(duan)(duan)外徑的1%,且不應(ying)大(da)于5mm;偏心(xin)異徑管過(guo)渡區(qu)應(ying)圓(yuan)滑。

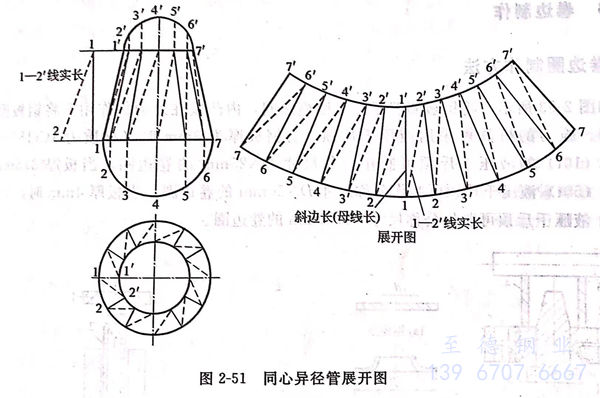

1. 同心異(yi)徑管展開圖

圖(tu)2-51為(wei)同(tong)心(xin)異徑管展開(kai)圖(tu),其作圖(tu)步驟如下(xia)。

①. 按已知(zhi)尺寸(cun)畫出主視(shi)圖和(he)俯視(shi)圖,將其(qi)上(shang)、下口分成12等份(fen),使表面組(zu)成24個三角形(xing)。

②. 采用直(zhi)角(jiao)三角(jiao)形法求出1-2'線的實長(chang)。

③. 按照已知三邊作(zuo)三角形的方(fang)法,即可得(de)到同(tong)心異(yi)徑管的展開圖。

2. 不(bu)銹鋼異徑(jing)管的制作(zuo)

不銹鋼異徑管分同(tong)心和偏(pian)心兩種,可用卷焊、摔制、抽條等方法制作。

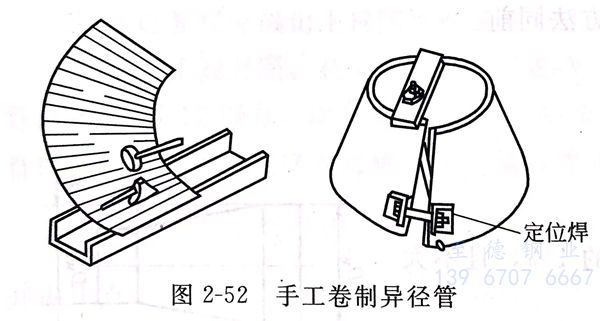

采(cai)用(yong)(yong)(yong)(yong)鋼(gang)板(ban)卷焊時(shi),先作(zuo)出樣(yang)板(ban),然(ran)后將樣(yang)板(ban)平鋪在鋼(gang)板(ban)上劃(hua)線、下(xia)料,并按要(yao)(yao)求(qiu)加(jia)工坡口(kou),除(chu)去毛(mao)刺和氧化鐵皮,用(yong)(yong)(yong)(yong)滾(gun)板(ban)機或壓力機卷圓,再用(yong)(yong)(yong)(yong)1/4圓的弧(hu)形樣(yang)板(ban)檢查(cha)(cha)內圓的弧(hu)度。經修理(li)達到(dao)要(yao)(yao)求(qiu)后施焊。無機械(xie)卷圓時(shi),也可(ke)用(yong)(yong)(yong)(yong)手工卷制(zhi)(zhi),如圖2-52所示。制(zhi)(zhi)作(zuo)時(shi),先在切割(ge)好的鋼(gang)板(ban)上分區域劃(hua)線條,按區向內敲打(da)彎制(zhi)(zhi),錘擊力量(liang)要(yao)(yao)適當,以(yi)免(mian)用(yong)(yong)(yong)(yong)力過(guo)大鋼(gang)板(ban)產(chan)生過(guo)度變形,并隨時(shi)用(yong)(yong)(yong)(yong)1/4圓弧(hu)形樣(yang)板(ban)檢查(cha)(cha);發現扭曲不對口(kou)時(shi),可(ke)用(yong)(yong)(yong)(yong)工具校正。

當管(guan)(guan)(guan)(guan)徑較小、采(cai)用鋼板(ban)卷制(zhi)(zhi)有困難時(shi)(shi),異徑管(guan)(guan)(guan)(guan)可(ke)用鋼管(guan)(guan)(guan)(guan)摔(shuai)制(zhi)(zhi)。制(zhi)(zhi)作(zuo)時(shi)(shi),先用烘爐或氧-乙炔焰將管(guan)(guan)(guan)(guan)子加熱(re)到(dao)800~950℃.摔(shuai)同心(xin)異徑管(guan)(guan)(guan)(guan)時(shi)(shi),邊錘(chui)擊邊轉動管(guan)(guan)(guan)(guan)子,由大到(dao)小,使(shi)管(guan)(guan)(guan)(guan)面圓(yuan)弧均(jun)勻(yun)過渡,錘(chui)面要放(fang)平(ping),防止錘(chui)擊時(shi)(shi)使(shi)管(guan)(guan)(guan)(guan)壁產生(sheng)麻(ma)面。一遍摔(shuai)不好時(shi)(shi),可(ke)再(zai)加熱(re),直(zhi)到(dao)摔(shuai)成為止。摔(shuai)偏(pian)心(xin)大小頭時(shi)(shi),管(guan)(guan)(guan)(guan)下壁不應(ying)(ying)加熱(re),采(cai)用烘爐加熱(re)時(shi)(shi),可(ke)用水將管(guan)(guan)(guan)(guan)下壁冷卻(que)后再(zai)摔(shuai)管(guan)(guan)(guan)(guan)。摔(shuai)制(zhi)(zhi)時(shi)(shi),應(ying)(ying)左右轉動,使(shi)其過渡圓(yuan)滑。

制作異徑(jing)(jing)(jing)管(guan)時,其(qi)變(bian)徑(jing)(jing)(jing)過渡(du)區的長度視管(guan)徑(jing)(jing)(jing)不(bu)同而(er)異,為減小(xiao)局部阻力,一般不(bu)應小(xiao)于大管(guan)外徑(jing)(jing)(jing)。