1. 電解拋(pao)光工藝流程

不銹(xiu)鋼管化學除油→熱水(shui)沖(chong)(chong)洗→清水(shui)漂(piao)洗→烘(hong)干→電(dian)解拋(pao)光→清水(shui)沖(chong)(chong)洗→熱水(shui)沖(chong)(chong)洗→清水(shui)漂(piao)洗→(鈍化處理→熱水(shui)沖(chong)(chong)洗→清水(shui)漂(piao)洗→中和→熱水(shui)沖(chong)(chong)洗→)→烘(hong)干→檢驗→包(bao)裝→出廠。

2. 化學(xue)除油

化學除油配(pei)方:

NaOH: 50g/L~80g/L; Na2CO3: 20g/L~30g/L; Na3PO3: 20g/L~30g/L;

洗衣粉:7g/L~10g/L;溫(wen)度(du):80℃~90℃;時間:15min.

3. 電解拋光工藝(yi)

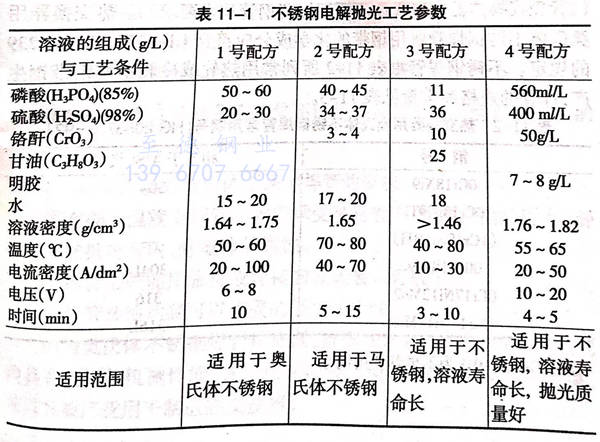

電(dian)(dian)解(jie)拋光工(gong)(gong)(gong)藝(yi)主要(yao)(yao)包括電(dian)(dian)解(jie)液的(de)(de)(de)(de)配(pei)制,電(dian)(dian)解(jie)液的(de)(de)(de)(de)溫度(du),電(dian)(dian)解(jie)拋光的(de)(de)(de)(de)時間、電(dian)(dian)流和電(dian)(dian)壓等。下面(mian)介紹幾種常用(yong)(yong)的(de)(de)(de)(de)不銹(xiu)鋼電(dian)(dian)解(jie)拋光液配(pei)方及其工(gong)(gong)(gong)藝(yi)參數。這(zhe)些配(pei)方所用(yong)(yong)的(de)(de)(de)(de)化學藥品都(dou)是(shi)最(zui)普(pu)通的(de)(de)(de)(de)容易購買到(dao)的(de)(de)(de)(de),而且工(gong)(gong)(gong)藝(yi)要(yao)(yao)求的(de)(de)(de)(de)溫度(du)都(dou)比較低,拋光所需時間也較短(duan),非常適合于大生產的(de)(de)(de)(de)要(yao)(yao)求 而日(ri)地光效果理想可靠,見表(biao)11-1。

4. 鈍化

鈍化液配方:HNO3: (d=1.40)600ml/L~700ml/L;重鉻酸鉀:8g/L~10g/L;溫度:常溫;時間:30min.

5. 中和

中和液配方及工藝條件:Na2CO3: 20g/L~30g/L;溫度:常溫;時間:2min.