不銹鋼表面有焊(han)縫(feng),且(qie)油污較重,采用1號工(gong)(gong)藝流程:手工(gong)(gong)除焊(han)瘤、毛刺(ci)、焊(han)渣等→手工(gong)(gong)去油(汽油擦洗(xi))→化(hua)學(xue)除油(氫氧(yang)(yang)化(hua)鈉30~65g/L,碳(tan)酸(suan)鈉20~40g/L,磷酸(suan)鈉20~35g/L,OP-10乳(ru)化(hua)劑2~3mL/L,60~80℃,除盡(jin)為止(zhi),一般為20~30分鐘(zhong))→水(shui)(shui)洗(xi)→化(hua)學(xue)拋光→水(shui)(shui)洗(xi)→中(zhong)和(碳(tan)酸(suan)鈉3~5g/L,氫氧(yang)(yang)化(hua)鈉1~2g/L,室溫,時間0.5~1h)→水(shui)(shui)洗(xi)→干燥(zao)→驗收。

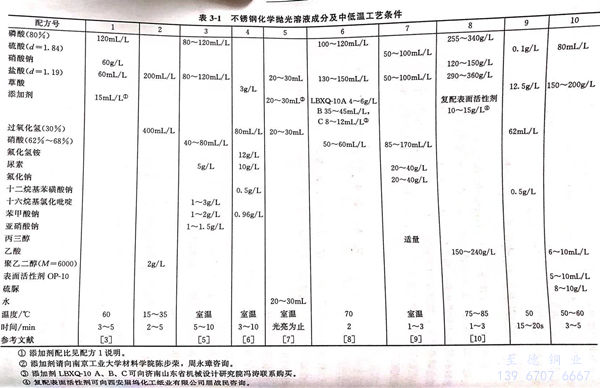

不銹鋼表(biao)面油(you)漬很(hen)輕而有較薄的氧化(hua)(hua)皮者可(ke)采(cai)用2號工藝流程:化(hua)(hua)學除油(you)→水(shui)(shui)洗(xi)→酸(suan)(suan)洗(xi)(硫(liu)酸(suan)(suan)300~400g/L,氫(qing)氟酸(suan)(suan)80~140g/L,室溫(wen)(wen),時(shi)間(jian)5~10min)→水(shui)(shui)洗(xi)→活(huo)化(hua)(hua)(硫(liu)酸(suan)(suan)10mL/L,鹽酸(suan)(suan)1mL/L,溫(wen)(wen)度40~60℃,時(shi)間(jian)以零件析(xi)出氣(qi)體(ti)10~20秒即(ji)可(ke))→水(shui)(shui)洗(xi)→化(hua)(hua)學拋光(見表(biao)3-1)→水(shui)(shui)洗(xi)→鈍化(hua)(hua)[硝酸(suan)(suan)(d=1.42)450mL/L,硫(liu)酸(suan)(suan)(d=1.84)50mL/L,溫(wen)(wen)度60~70℃,時(shi)間(jian)2~3min]→水(shui)(shui)洗(xi)→中和[氨水(shui)(shui)(d=0.889)2%(質量分數),室溫(wen)(wen),5~10分鐘]→水(shui)(shui)洗(xi)→脫水(shui)(shui)→烘(hong)干→驗收。

如果需要電(dian)鍍(du)、著色等,則在化學拋光和水洗(xi)后即可轉入下(xia)道工序進行加工。