浙江至德鋼業有限公司技術人員用壓力將經過加熱的不銹鋼彎頭推向一個后端加以固定的頂桿,該頂桿的頂頭位于由一對軋輥組成的圓孔型的中心,因此軸向的推力和徑向的軋制力同時作用在方坯上,使彎頭經過頂頭和圓孔型穿孔成為空心坯。在變形過程中只出現壓應力、基本上消除了拉伸應力、剪切應力和連續滑動現象,故穿孔后的不銹鋼彎頭的金屬組織大大改善。

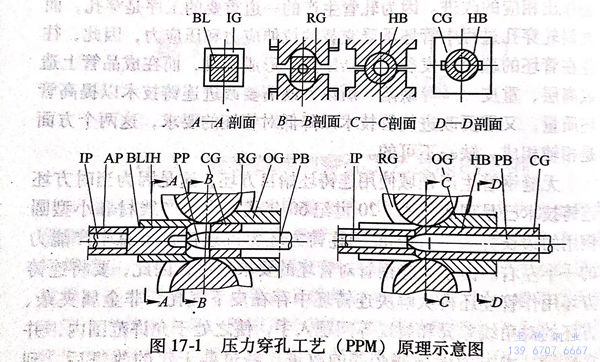

如圖17-1所(suo)示(shi),經(jing)過(guo)加(jia)熱的(de)(de)(de)不銹鋼彎頭(tou)BL經(jing)消除氧化鐵皮和(he)(he)定(ding)(ding)型(xing)后,被(bei)送(song)至(zhi)壓力(li)(li)穿孔(kong)(kong)機的(de)(de)(de)受料槽內,并處于液壓推(tui)(tui)(tui)鋼機AP和(he)(he)軋機機架間。液力(li)(li)推(tui)(tui)(tui)鋼機AP將經(jing)過(guo)熱定(ding)(ding)心(xin)(xin)的(de)(de)(de)方坯(pi)(pi)推(tui)(tui)(tui)入(ru)(ru)一個堅固的(de)(de)(de)、公(gong)差很小的(de)(de)(de)方形(xing)入(ru)(ru)口導(dao)(dao)套(tao)(tao)IG,使方坯(pi)(pi)同(tong)(tong)(tong)時(shi)和(he)(he)穿孔(kong)(kong)機頭(tou)PP和(he)(he)軋輥RG相遇(yu),并在(zai)(zai)(zai)整個穿孔(kong)(kong)過(guo)程維持(chi)恒定(ding)(ding)的(de)(de)(de)推(tui)(tui)(tui)力(li)(li),然(ran)后即作用在(zai)(zai)(zai)它(ta)圓形(xing)的(de)(de)(de)外表面上,當(dang)空(kong)心(xin)(xin)坯(pi)(pi)HB由(you)軋輥孔(kong)(kong)型(xing)中(zhong)軋出時(shi),立(li)即進入(ru)(ru)堅固的(de)(de)(de)配(pei)合得(de)很緊密(mi)的(de)(de)(de)出口中(zhong)導(dao)(dao)套(tao)(tao)OG.導(dao)(dao)環(huan)(huan)CG,在(zai)(zai)(zai)穿孔(kong)(kong)開(kai)始(shi)時(shi)位于頂(ding)桿PB的(de)(de)(de)前(qian)端,而(er)當(dang)空(kong)心(xin)(xin)坯(pi)(pi)進入(ru)(ru)出口導(dao)(dao)套(tao)(tao)0G時(shi),它(ta)與(yu)導(dao)(dao)環(huan)(huan)CG相遇(yu),并推(tui)(tui)(tui)動(dong)(dong)導(dao)(dao)環(huan)(huan)CG前(qian)進而(er)空(kong)心(xin)(xin)坯(pi)(pi)本身逐(zhu)漸起到定(ding)(ding)心(xin)(xin)的(de)(de)(de)作用。因此(ci)只要正(zheng)確地調整入(ru)(ru)口導(dao)(dao)套(tao)(tao)IG,軋輥RG和(he)(he)出口導(dao)(dao)套(tao)(tao)OG即可保證不銹鋼彎頭(tou)、頂(ding)頭(tou)與(yu)頂(ding)桿三者的(de)(de)(de)中(zhong)心(xin)(xin)線在(zai)(zai)(zai)同(tong)(tong)(tong)一直線上,故(gu)壓力(li)(li)穿孔(kong)(kong)后,空(kong)心(xin)(xin)坯(pi)(pi)壁厚比(bi)較均勻(yun)。當(dang)穿孔(kong)(kong)操作將要結束時(shi),液力(li)(li)推(tui)(tui)(tui)鋼機的(de)(de)(de)柱(zhu)塞桿IP自(zi)動(dong)(dong)停止(zhi)前(qian)進,而(er)推(tui)(tui)(tui)鋼機外環(huan)(huan)繼續前(qian)進,直至(zhi)與(yu)頂(ding)頭(tou)相遇(yu)為止(zhi),此(ci)時(shi)不銹鋼彎頭(tou)后部的(de)(de)(de)穿孔(kong)(kong)全靠徑向軋制力(li)(li)來完成。方坯(pi)(pi)穿孔(kong)(kong)后,打開(kai)鎖門(men),水冷頂(ding)桿由(you)空(kong)心(xin)(xin)坯(pi)(pi)內抽出,其(qi)動(dong)(dong)作和(he)(he)斜軋穿孔(kong)(kong)機是(shi)相同(tong)(tong)(tong)的(de)(de)(de)。