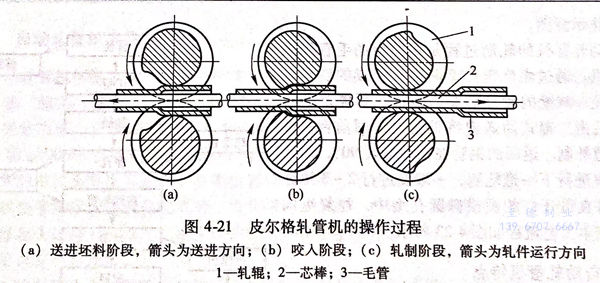

這種軋機(ji)亦稱(cheng)皮爾格軋管機(ji),1891年由曼乃斯曼兄弟發明(ming),1900年將芯棒設計成移(yi)動式為止才(cai)達到完全機(ji)械化,成為目前狀態,其操(cao)作過程如圖4-21所示。

此軋(ya)(ya)(ya)(ya)機操作的(de)基本特(te)點(dian)(dian)是鍛(duan)軋(ya)(ya)(ya)(ya),軋(ya)(ya)(ya)(ya)輥(gun)旋轉方向與軋(ya)(ya)(ya)(ya)件送(song)(song)(song)進方向相反,軋(ya)(ya)(ya)(ya)輥(gun)孔(kong)型(xing)沿圓(yuan)周(zhou)為(wei)(wei)變斷面,軋(ya)(ya)(ya)(ya)制(zhi)時軋(ya)(ya)(ya)(ya)件反送(song)(song)(song)進方向運行。送(song)(song)(song)料由(you)做往復運動的(de)芯(xin)棒(bang)送(song)(song)(song)進機構完(wan)成,這種軋(ya)(ya)(ya)(ya)制(zhi)形式的(de)延伸系數為(wei)(wei)7~15,可(ke)用(yong)鋼錠直接(jie)生(sheng)(sheng)產。目前主要用(yong)于(yu)生(sheng)(sheng)產大直徑中(zhong)、厚(hou)壁(bi)管(guan)(guan)、異形管(guan)(guan),利用(yong)鍛(duan)軋(ya)(ya)(ya)(ya)的(de)特(te)點(dian)(dian)還可(ke)生(sheng)(sheng)產合金鋼管(guan)(guan)。生(sheng)(sheng)產的(de)規(gui)格范(fan)圍(wei)外徑為(wei)(wei)114~665mm;壁(bi)厚(hou)2.5~100mm;軋(ya)(ya)(ya)(ya)后長度(du)可(ke)達40m.該軋(ya)(ya)(ya)(ya)機的(de)主要缺(que)點(dian)(dian)是:效率低,輔(fu)助(zhu)操作時間(jian)占整個周(zhou)期的(de)25%;孔(kong)型(xing)不易加(jia)工;芯(xin)棒(bang)長,生(sheng)(sheng)產規(gui)格范(fan)圍(wei)窄,壁(bi)厚(hou)精(jing)度(du)低。為(wei)(wei)減(jian)(jian)少周(zhou)期,軋(ya)(ya)(ya)(ya)機皆采用(yong)線(xian)外插芯(xin)棒(bang)鍛(duan)頭(tou),再送(song)(song)(song)往主機軋(ya)(ya)(ya)(ya)制(zhi),以減(jian)(jian)少輔(fu)助(zhu)操作時間(jian)。為(wei)(wei)改善周(zhou)期軋(ya)(ya)(ya)(ya)機加(jia)工的(de)規(gui)格尺寸窄的(de)問題,有的(de)配以張力減(jian)(jian)徑來擴大機組(zu)生(sheng)(sheng)產規(gui)格范(fan)圍(wei)。