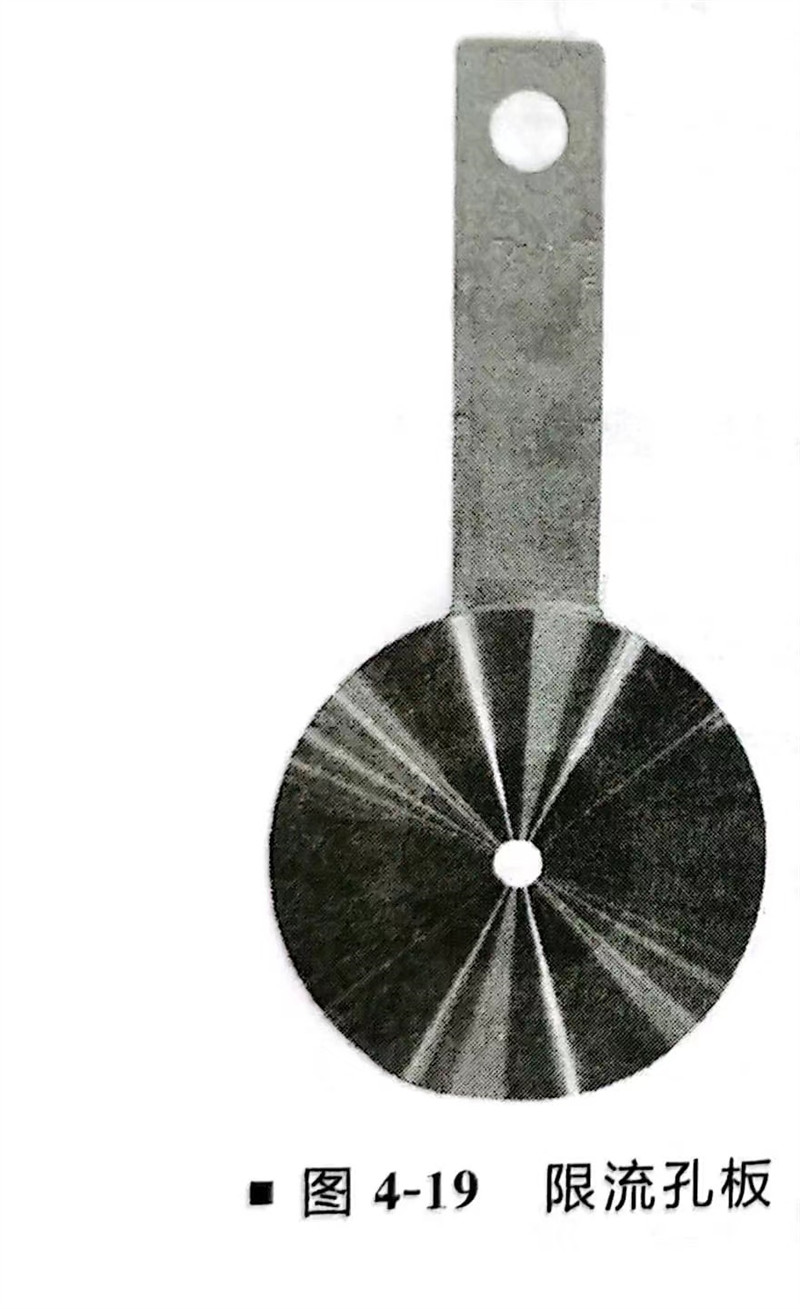

限流孔板(ban)(ban)(Restriction Orifice)是在板(ban)(ban)面上開一個小(xiao)錐(zhui)孔(該(gai)小(xiao)錐(zhui)孔的尺寸(cun)由工藝專(zhuan)業提(ti)出(chu)),如圖4-19所(suo)示。它也(ye)應(ying)有兩個和匹(pi)配法蘭(lan)同樣的密封(feng)面。限流孔板(ban)(ban)可以作為流量測量(liang)元(yuan)件(jian)用來(lai)測量(liang)流(liu)(liu)量(liang),也可(ke)以作為節流(liu)(liu)元(yuan)件(jian)用來(lai)限(xian)定流(liu)(liu)量(liang)和降低壓(ya)(ya)力。當孔(kong)(kong)(kong)(kong)板(ban)(ban)前后(hou)存在(zai)一定壓(ya)(ya)差(cha),流(liu)(liu)體(ti)流(liu)(liu)經孔(kong)(kong)(kong)(kong)板(ban)(ban),對于一定的孔(kong)(kong)(kong)(kong)徑,流(liu)(liu)經孔(kong)(kong)(kong)(kong)板(ban)(ban)的流(liu)(liu)量(liang)隨著壓(ya)(ya)差(cha)增大而增大。但當壓(ya)(ya)差(cha)超過某一數值(稱為臨界壓(ya)(ya)差(cha))時,流(liu)(liu)體(ti)通過孔(kong)(kong)(kong)(kong)板(ban)(ban)縮(suo)孔(kong)(kong)(kong)(kong)處的流(liu)(liu)速達到(dao)音(yin)速,這時,無論壓(ya)(ya)差(cha)如何增加,流(liu)(liu)經孔(kong)(kong)(kong)(kong)板(ban)(ban)的流(liu)(liu)量(liang)將維持在(zai)一定數值而不再增加。限(xian)流(liu)(liu)孔(kong)(kong)(kong)(kong)板(ban)(ban)就是根據這一原理來(lai)限(xian)定流(liu)(liu)體(ti)的流(liu)(liu)量(liang)和降低壓(ya)(ya)力的。限(xian)流(liu)(liu)孔(kong)(kong)(kong)(kong)板(ban)(ban)按孔(kong)(kong)(kong)(kong)板(ban)(ban)上(shang)開孔(kong)(kong)(kong)(kong)數量(liang)分為單(dan)孔(kong)(kong)(kong)(kong)板(ban)(ban)和多孔(kong)(kong)(kong)(kong)板(ban)(ban);按孔(kong)(kong)(kong)(kong)板(ban)(ban)數量(liang)可(ke)分為單(dan)級和多級。

限流孔(kong)板主(zhu)要使(shi)用在下列場合:

①. 工藝物料需(xu)要(yao)降壓(ya)的場合(he)。

②. 在(zai)管道中閥門(men)上(shang)、下游(you)需要(yao)有較(jiao)大壓降(jiang)時,為減少流體對閥門(men)的沖蝕,當經(jing)孔(kong)板節流不(bu)會產生氣(qi)相時,可在(zai)閥門(men)上(shang)游(you)串聯孔(kong)板。

③. 流(liu)(liu)體(ti)需(xu)要小流(liu)(liu)量且連(lian)續(xu)流(liu)(liu)通的地方,如泵(beng)的沖(chong)洗管(guan)道(dao)、熱備用泵(beng)的旁(pang)路(lu)管(guan)道(dao)(低流(liu)(liu)量保護管(guan)道(dao))、分析取樣管(guan)等場所(suo)。

④. 需要降壓以減少噪聲或磨(mo)損的地方,如(ru)放空系統(tong)。

限流孔板有(you)關的標準有(you):HG/T 20570.15、ISO 5167和GB/T 2624。

混合(he)(he)孔板(ban)(Mixing Orifice)是在(zai)板(ban)面(mian)上開設一個(ge)或若干個(ge)小孔,以便于兩(liang)種介質(zhi)在(zai)經過混合(he)(he)孔板(ban)時能充分(fen)混合(he)(he)而達(da)到工藝操作(zuo)的目的。它也應有(you)兩(liang)個(ge)和(he)匹配法蘭同(tong)樣的密封面(mian)。