給(gei)排水(shui)系(xi)統的合理設置及給(gei)排水(shui)管(guan)(guan)道(dao)的管(guan)(guan)材(cai)(cai)、防腐、閥門等(deng)的合理選擇,防止了地(di)(di)下(xia)水(shui)和土壤受到污染,保證了石油化工(gong)企業安全運行。埋地(di)(di)給(gei)排水(shui)管(guan)(guan)道(dao)用(yong)的管(guan)(guan)材(cai)(cai)應根(gen)據內水(shui)壓(ya)力、流量、環(huan)境介質(zhi)及管(guan)(guan)材(cai)(cai)材(cai)(cai)質(zhi)等(deng)綜合因素確定。

1. 給排(pai)水(shui)系統(tong)

石化給(gei)(gei)排水(shui)(shui)系(xi)(xi)統(tong)(tong)一般可分為(wei)給(gei)(gei)水(shui)(shui)系(xi)(xi)統(tong)(tong)和(he)排水(shui)(shui)系(xi)(xi)統(tong)(tong)。給(gei)(gei)水(shui)(shui)系(xi)(xi)統(tong)(tong)包括生(sheng)活(huo)給(gei)(gei)水(shui)(shui)、生(sheng)產(chan)給(gei)(gei)水(shui)(shui)、循(xun)環水(shui)(shui)、消防水(shui)(shui)及回用水(shui)(shui)系(xi)(xi)統(tong)(tong)。排水(shui)(shui)系(xi)(xi)統(tong)(tong)可分為(wei)含油污(wu)(wu)水(shui)(shui)系(xi)(xi)統(tong)(tong)、生(sheng)產(chan)污(wu)(wu)水(shui)(shui)系(xi)(xi)統(tong)(tong)、清凈雨水(shui)(shui)系(xi)(xi)統(tong)(tong)、生(sheng)活(huo)污(wu)(wu)水(shui)(shui)系(xi)(xi)統(tong)(tong)等。

①. 含(han)(han)油(you)(you)(you)污(wu)水(shui)系統主要排(pai)(pai)放(fang)各生(sheng)產裝置、輔助設施排(pai)(pai)出的含(han)(han)油(you)(you)(you)污(wu)水(shui),含(han)(han)油(you)(you)(you)污(wu)水(shui)通過排(pai)(pai)污(wu)井或漏斗收集(ji),重力流(liu)進(jin)入(ru)隔油(you)(you)(you)池,預處理(li)(li)后(hou)由泵提升(sheng)至廠區內污(wu)水(shui)處理(li)(li)場處理(li)(li)達標后(hou)排(pai)(pai)放(fang)。裝置污(wu)染(ran)區15min 前的初期雨水(shui)也進(jin)入(ru)含(han)(han)油(you)(you)(you)污(wu)水(shui)系統。

②. 生產(chan)污水(shui)系(xi)統主要排放裝置污染區15min以后的后期(qi)雨水(shui),通過明溝收集進(jin)入生產(chan)污水(shui)系(xi)統,經泵(beng)加壓提升(sheng)至污水(shui)處理(li)(li)場處理(li)(li)達標后排放。

③. 清凈雨(yu)水系統為廠(chang)區道(dao)路雨(yu)水,通過管道(dao)收集后(hou)進入雨(yu)水調峰池,經(jing)監(jian)測無污染后(hou)可直接外(wai)排(pai)或處理(li)后(hou)再(zai)利用。

④. 生(sheng)活(huo)污(wu)(wu)(wu)(wu)水(shui)(shui)系統(tong)來自(zi)廁(ce)所、食堂、浴室生(sheng)活(huo)污(wu)(wu)(wu)(wu)水(shui)(shui),經化(hua)糞(fen)池后壓力排往污(wu)(wu)(wu)(wu)水(shui)(shui)處理場的生(sheng)化(hua)池。生(sheng)活(huo)污(wu)(wu)(wu)(wu)水(shui)(shui)需單獨收(shou)集,個別生(sheng)活(huo)污(wu)(wu)(wu)(wu)水(shui)(shui)需排入(ru)生(sheng)產污(wu)(wu)(wu)(wu)水(shui)(shui)、含(han)油污(wu)(wu)(wu)(wu)水(shui)(shui)系統(tong)時,在接入(ru)前需設(she)水(shui)(shui)封(feng)設(she)施,以防止生(sheng)產污(wu)(wu)(wu)(wu)水(shui)(shui)系統(tong)的有害氣體竄入(ru)生(sheng)活(huo)設(she)施。

2. 管材選用(yong)

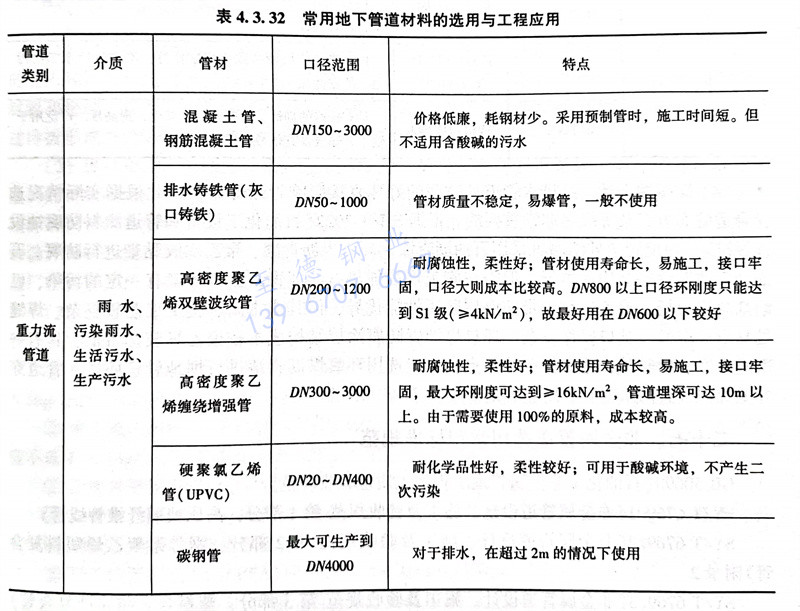

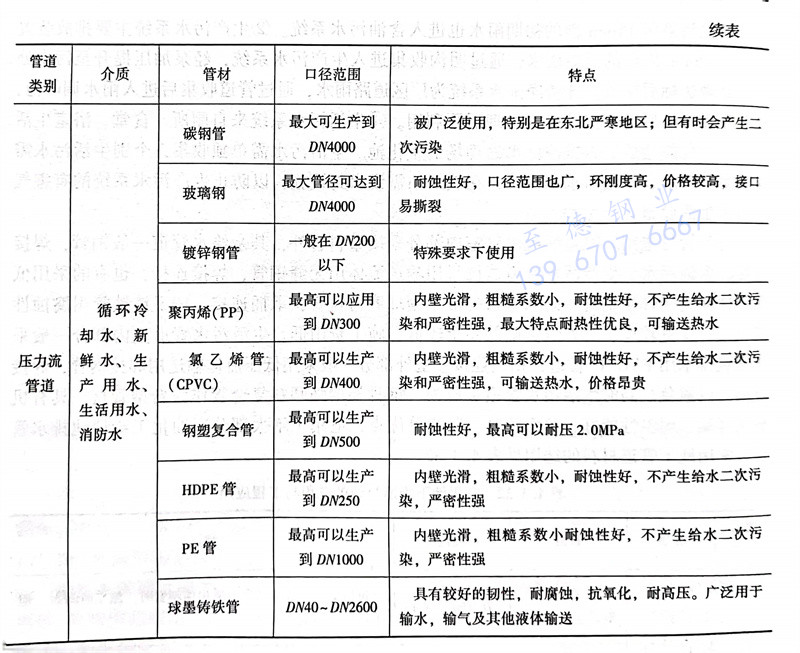

除生(sheng)活給水(shui)(shui)管(guan)(guan)(guan)(guan)(guan)室(shi)內部分采用(yong)(yong)塑料管(guan)(guan)(guan)(guan)(guan)外,其余(yu)給水(shui)(shui)管(guan)(guan)(guan)(guan)(guan)道一(yi)般(ban)(ban)(ban)鋼(gang)(gang)管(guan)(guan)(guan)(guan)(guan),焊接(jie)連(lian)接(jie)。含(han)油(you)污水(shui)(shui)、生(sheng)產(chan)污水(shui)(shui)管(guan)(guan)(guan)(guan)(guan)道建議采用(yong)(yong)輸送(song)流體(ti)用(yong)(yong)無縫鋼(gang)(gang)管(guan)(guan)(guan)(guan)(guan),焊接(jie)連(lian)接(jie),也有的(de)采用(yong)(yong)低(di)壓流體(ti)輸送(song)用(yong)(yong)焊接(jie)鋼(gang)(gang)管(guan)(guan)(guan)(guan)(guan)。雨(yu)水(shui)(shui)管(guan)(guan)(guan)(guan)(guan)道一(yi)般(ban)(ban)(ban)采用(yong)(yong)球磨鑄(zhu)鐵(tie)管(guan)(guan)(guan)(guan)(guan),承插連(lian)接(jie)。球墨鑄(zhu)鐵(tie)管(guan)(guan)(guan)(guan)(guan)耐腐蝕性能較(jiao)強、管(guan)(guan)(guan)(guan)(guan)壁較(jiao)厚、對管(guan)(guan)(guan)(guan)(guan)道基礎(chu)的(de)要求較(jiao)低(di)、施工費用(yong)(yong)低(di)。生(sheng)活污水(shui)(shui)管(guan)(guan)(guan)(guan)(guan)道室(shi)內部分一(yi)般(ban)(ban)(ban)采用(yong)(yong)建筑排(pai)水(shui)(shui)用(yong)(yong)PVC-U管(guan)(guan)(guan)(guan)(guan)道,粘接(jie)連(lian)接(jie);室(shi)外部分一(yi)般(ban)(ban)(ban)采用(yong)(yong)低(di)壓流體(ti)輸送(song)用(yong)(yong)焊接(jie)鋼(gang)(gang)管(guan)(guan)(guan)(guan)(guan),焊接(jie)連(lian)接(jie),以避免過路時生(sheng)活污水(shui)(shui)管(guan)(guan)(guan)(guan)(guan)道被壓損。鋼(gang)(gang)骨(gu)架(jia)增強塑料復合管(guan)(guan)(guan)(guan)(guan)作為新型管(guan)(guan)(guan)(guan)(guan)材(cai),具(ju)有機械強度高、耐溫性能好、雙面(mian)防腐、節能等優(you)點,適用(yong)(yong)于絕大(da)部分石油(you)化(hua)工給埋地排(pai)水(shui)(shui)管(guan)(guan)(guan)(guan)(guan)道。常用(yong)(yong)地下管(guan)(guan)(guan)(guan)(guan)道材(cai)料的(de)選(xuan)用(yong)(yong)見表4.3.32。

3. 防腐蝕設計

給排水管(guan)(guan)道(dao)(dao)外防(fang)腐(fu)(fu)的好壞直接影響管(guan)(guan)道(dao)(dao)壽命(ming),因此根據(ju)實際情況選擇合適(shi)防(fang)腐(fu)(fu)方(fang)案及等(deng)級是非常重要(yao)的。根據(ju)SH/T 3022《石(shi)油(you)(you)化工設(she)備和管(guan)(guan)道(dao)(dao)涂(tu)(tu)料防(fang)腐(fu)(fu)蝕設(she)計標準》,埋地(di)管(guan)(guan)道(dao)(dao)外防(fang)腐(fu)(fu)可采用石(shi)油(you)(you)瀝(li)(li)青漆、環(huan)(huan)(huan)氧(yang)煤(mei)瀝(li)(li)青漆、聚(ju)乙(yi)烯膠(jiao)黏帶進(jin)行(xing)防(fang)腐(fu)(fu)。石(shi)油(you)(you)瀝(li)(li)青防(fang)腐(fu)(fu)涂(tu)(tu)層結構成(cheng)(cheng)本(ben)低,但(dan)需在施(shi)工現場加熱石(shi)油(you)(you)瀝(li)(li)青,且對環(huan)(huan)(huan)境(jing)有(you)一定的污染,已漸(jian)漸(jian)淡(dan)出市場。聚(ju)乙(yi)烯膠(jiao)黏帶防(fang)腐(fu)(fu)層防(fang)腐(fu)(fu)性(xing)能優(you)異,但(dan)其成(cheng)(cheng)本(ben)高、施(shi)工工藝較(jiao)復雜、焊(han)縫(feng)處(chu)易(yi)形(xing)成(cheng)(cheng)空鼓、補口操作復雜。環(huan)(huan)(huan)氧(yang)煤(mei)瀝(li)(li)青防(fang)腐(fu)(fu)涂(tu)(tu)層結構成(cheng)(cheng)本(ben)較(jiao)聚(ju)乙(yi)烯膠(jiao)黏帶低,具有(you)一次成(cheng)(cheng)膜(mo)厚、耐酸堿、施(shi)工簡單等(deng)優(you)點(dian),一般選用環(huan)(huan)(huan)氧(yang)煤(mei)瀝(li)(li)青漆進(jin)行(xing)埋地(di)管(guan)(guan)道(dao)(dao)防(fang)腐(fu)(fu)。管(guan)(guan)道(dao)(dao)穿井壁處(chu)需設(she)置防(fang)水套管(guan)(guan),防(fang)止管(guan)(guan)道(dao)(dao)泄漏。