埋弧焊焊接奧氏體型不銹鋼管施焊工藝、程序基本與焊接碳鋼管相同,大致有以下幾種。

①. 焊條電弧焊與埋弧焊組合(he)施(shi)焊

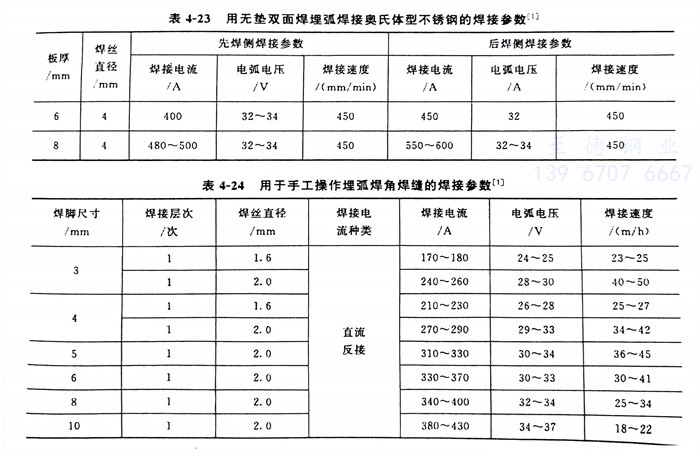

先用焊(han)條電弧焊(han)打底焊(han)(backing welding),要求焊(han)條電弧焊(han)的(de)熔深達到(dao)板(ban)厚的(de)1/3,焊(han)完以(yi)后,清理焊(han)縫(feng)。清除掉焊(han)縫(feng)缺陷后,在另(ling)一方面進行(xing)埋弧焊(han),如圖4-23所示。

②. 永久墊板埋弧(hu)焊

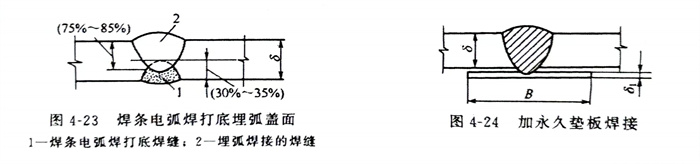

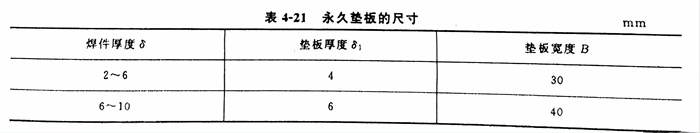

焊(han)(han)(han)(han)件裝配(pei)時(shi)將同(tong)種(zhong)不(bu)銹鋼管(guan)的(de)墊(dian)(dian)(dian)板(ban)(ban)(ban)緊密地貼在接頭下部(bu)用定位(wei)焊(han)(han)(han)(han)固(gu)定,進(jin)行單面熔(rong)透焊(han)(han)(han)(han)的(de)一種(zhong)埋弧焊(han)(han)(han)(han)工(gong)藝(yi)。此時(shi)要求墊(dian)(dian)(dian)板(ban)(ban)(ban)與(yu)焊(han)(han)(han)(han)件之間(jian)的(de)間(jian)隙(xi)(xi)不(bu)得超過0.5~1.0mm,否則(ze)液態金(jin)屬或熔(rong)渣必然從間(jian)隙(xi)(xi)處流出或嵌入夾(jia)縫中(zhong)間(jian)而造(zao)成(cheng)焊(han)(han)(han)(han)接缺陷。焊(han)(han)(han)(han)接完畢,墊(dian)(dian)(dian)板(ban)(ban)(ban)有一部(bu)分金(jin)屬被熔(rong)入焊(han)(han)(han)(han)縫形成(cheng)焊(han)(han)(han)(han)縫金(jin)屬,與(yu)焊(han)(han)(han)(han)件牢固(gu)地焊(han)(han)(han)(han)在一起(qi)。故(gu)要求墊(dian)(dian)(dian)板(ban)(ban)(ban)的(de)化學(xue)成(cheng)分、力(li)學(xue)性(xing)(xing)能和耐腐(fu)蝕性(xing)(xing)能與(yu)焊(han)(han)(han)(han)件相同(tong)。永久(jiu)墊(dian)(dian)(dian)板(ban)(ban)(ban)的(de)尺寸見表4-21。永久(jiu)墊(dian)(dian)(dian)板(ban)(ban)(ban)焊(han)(han)(han)(han)接時(shi)的(de)裝配(pei)示意圖(tu)如(ru)(ru)圖(tu)4-24所示。焊(han)(han)(han)(han)接壓力(li)容器封頭與(yu)筒體的(de)環焊(han)(han)(han)(han)縫時(shi),如(ru)(ru)果容器內部(bu)無(wu)法(fa)施焊(han)(han)(han)(han),且不(bu)會引起(qi)縫隙(xi)(xi)腐(fu)蝕時(shi),可用永久(jiu)墊(dian)(dian)(dian)板(ban)(ban)(ban)焊(han)(han)(han)(han)接工(gong)藝(yi)。

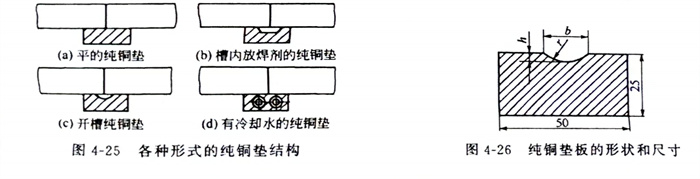

③. 純(chun)銅墊埋弧焊

這(zhe)種焊(han)(han)(han)接方(fang)法能(neng)使焊(han)(han)(han)接構(gou)件(jian)達到單(dan)面(mian)焊(han)(han)(han)背面(mian)成形的(de)(de)(de)(de)(de)目的(de)(de)(de)(de)(de)。純銅(tong)(tong)墊靠焊(han)(han)(han)接夾具緊(jin)貼(tie)待焊(han)(han)(han)接頭下(xia)面(mian),它與(yu)(yu)焊(han)(han)(han)件(jian)之間(jian)的(de)(de)(de)(de)(de)間(jian)隙不允許大于0.5mm,各(ge)種形式的(de)(de)(de)(de)(de)純銅(tong)(tong)墊結(jie)構(gou)如圖(tu)(tu)4-25所示(shi),純銅(tong)(tong)墊板(ban)的(de)(de)(de)(de)(de)形狀和尺寸(cun)見(jian)圖(tu)(tu)4-26和表4-22。在純銅(tong)(tong)墊接觸焊(han)(han)(han)件(jian)的(de)(de)(de)(de)(de)一面(mian)開槽,槽的(de)(de)(de)(de)(de)中心要與(yu)(yu)坡口根間(jian)隙對(dui)準,如果在槽內放焊(han)(han)(han)劑(ji)[見(jian)圖(tu)(tu)4-25(b)],則檀的(de)(de)(de)(de)(de)寬度(du)和深度(du)都要相應地加寬加深。

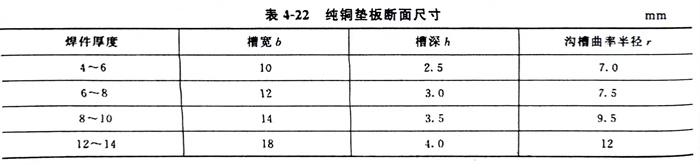

④. 鎖底對接(jie)接(jie)頭埋弧焊

這種焊接方(fang)法適用(yong)于厚度大于10mm的構件(jian),常用(yong)在小(xiao)直徑厚壁圓筒形(xing)焊件(jian)的環縫焊接,效(xiao)果很好(hao)。鎖底對(dui)接接頭見圖4-27。

⑤. 焊(han)劑(ji)墊埋弧焊(han)

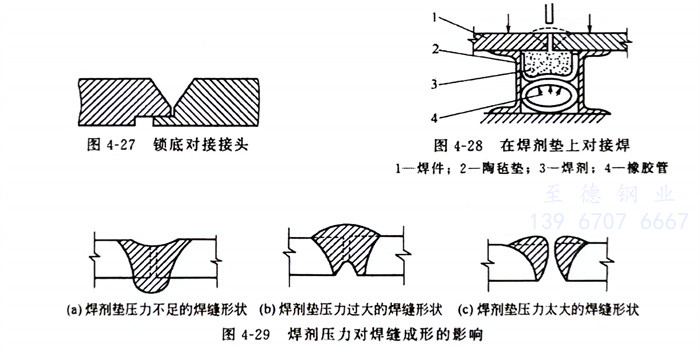

這種焊(han)(han)(han)接方法也可使焊(han)(han)(han)件達到(dao)單面(mian)(mian)(mian)焊(han)(han)(han)背面(mian)(mian)(mian)成(cheng)(cheng)形的(de)目的(de)。根(gen)據焊(han)(han)(han)件厚度,在(zai)接縫(feng)下面(mian)(mian)(mian)墊(dian)上一(yi)(yi)層厚度為30~100mm的(de)焊(han)(han)(han)劑(ji),焊(han)(han)(han)劑(ji)下面(mian)(mian)(mian)是一(yi)(yi)層絕緣的(de)陶氈墊(dian),陶氈墊(dian)下面(mian)(mian)(mian)是封閉的(de)橡(xiang)膠管,如圖4-28所示。坡口(kou)根(gen)部(bu)與焊(han)(han)(han)劑(ji)墊(dian)中(zhong)心要(yao)對(dui)中(zhong),當橡(xiang)膠管一(yi)(yi)端通入壓縮空氣時,焊(han)(han)(han)劑(ji)被均勻(yun)地(di)向上頂(ding)緊坡口(kou)的(de)根(gen)部(bu)。焊(han)(han)(han)接時,電弧將熔(rong)透焊(han)(han)(han)件并熔(rong)化一(yi)(yi)些(xie)焊(han)(han)(han)劑(ji),形成(cheng)(cheng)單面(mian)(mian)(mian)焊(han)(han)(han)雙面(mian)(mian)(mian)成(cheng)(cheng)形的(de)焊(han)(han)(han)縫(feng)。假若(ruo)焊(han)(han)(han)劑(ji)向上頂(ding)的(de)壓力過大或(huo)過小,在(zai)焊(han)(han)(han)縫(feng)背面(mian)(mian)(mian)會形成(cheng)(cheng)凹槽或(huo)突起(qi)部(bu)分,嚴重者(zhe)焊(han)(han)(han)縫(feng)不能成(cheng)(cheng)形,焊(han)(han)(han)劑(ji)壓力對(dui)焊(han)(han)(han)縫(feng)成(cheng)(cheng)形的(de)影響見圖4-29。

⑥. 雙面對接埋弧焊(han)

這是埋(mai)弧焊(han)(han)(han)焊(han)(han)(han)接(jie)對(dui)接(jie)焊(han)(han)(han)縫(feng)(feng)的一種(zhong)(zhong)基本方(fang)法,使(shi)用最廣。大多數中(zhong)、厚(hou)板焊(han)(han)(han)接(jie)時(shi)均(jun)使(shi)用雙面(mian)焊(han)(han)(han)。這種(zhong)(zhong)焊(han)(han)(han)接(jie)接(jie)頭的幾何(he)連(lian)續性最好,承載后應力狀態好,能適(shi)應工作負(fu)荷復(fu)雜和(he)苛刻的工作條件。故對(dui)焊(han)(han)(han)縫(feng)(feng)長(chang)度較(jiao)長(chang),分布規則(ze)的焊(han)(han)(han)縫(feng)(feng),應盡量采用這種(zhong)(zhong)施焊(han)(han)(han)工藝方(fang)法。此時(shi)第(di)一面(mian)施焊(han)(han)(han)也不用任何(he)形式襯墊(dian),在無墊(dian)焊(han)(han)(han)接(jie)時(shi),對(dui)焊(han)(han)(han)件邊緣的準備和(he)裝配質量要(yao)求較(jiao)高(gao),希望坡口根(gen)部(bu)間(jian)(jian)隙為(wei)零,局部(bu)根(gen)部(bu)間(jian)(jian)隙不得超過1.0mm,否則(ze)液體(ti)金屬容易(yi)從間(jian)(jian)隙中(zhong)流出而燒穿(chuan)(chuan)焊(han)(han)(han)縫(feng)(feng)或形成焊(han)(han)(han)瘤。為(wei)了有一定的熔深,同時(shi)又(you)不至于焊(han)(han)(han)穿(chuan)(chuan),通常在第(di)一面(mian)焊(han)(han)(han)接(jie)時(shi),要(yao)求熔深為(wei)鋼板厚(hou)度的60%~70%。如果(guo)被焊(han)(han)(han)件較(jiao)薄,在第(di)一面(mian)焊(han)(han)(han)接(jie)時(shi),可(ke)以采取(qu)減小焊(han)(han)(han)接(jie)電(dian)流,提高(gao)焊(han)(han)(han)接(jie)速度或者(zhe)焊(han)(han)(han)絲向(xiang)后傾斜等措施來避免燒穿(chuan)(chuan)。有關奧氏體(ti)型不銹鋼中(zhong)等厚(hou)度板材的無墊(dian)雙面(mian)埋(mai)弧焊(han)(han)(han)的焊(han)(han)(han)接(jie)參數見(jian)表4-23。