克虜伯·蒂森不銹鋼公司是于1995年由德國克虜伯公司和蒂森公司不銹鋼扁平材生產合并而組建的,1997年成立克虜伯·蒂森不銹鋼公司。隨之先后購買了意大利特爾尼特殊鋼公司(AST)90%的股權,又控股墨西哥不銹鋼公司(Mexinox),1997年,與中國上海浦東鋼鐵集團公司合資,興建上海克虜伯不銹鋼公司(SKS)。目前,克虜伯·蒂森不銹鋼公司在意大利AST公司的年產能力為130萬噸,其他四個主要子公司年產粗鋼的總能力為190萬噸,冷軋不銹鋼扁平材的總能力為165萬噸,這使克虜伯·蒂森不銹鋼公司成為世界最大的不銹鋼生產企業,其扁平材產品約占歐鄒市場份額的37%,世界市場份額的15%。

在(zai)(zai)(zai)全(quan)球鋼(gang)鐵(tie)公(gong)(gong)(gong)(gong)(gong)(gong)司(si)(si)合(he)并重(zhong)組浪潮的(de)(de)(de)(de)沖擊(ji)下(xia),克(ke)虜伯·蒂(di)森(sen)(sen)(sen)不(bu)銹(xiu)(xiu)(xiu)(xiu)鋼(gang)公(gong)(gong)(gong)(gong)(gong)(gong)司(si)(si)為(wei)維(wei)護其世界不(bu)銹(xiu)(xiu)(xiu)(xiu)鋼(gang)扁(bian)平(ping)材(cai)霸主的(de)(de)(de)(de)地位(wei),保(bao)持現有的(de)(de)(de)(de)市場(chang)份額,與(yu)(yu)諸如新合(he)并重(zhong)組的(de)(de)(de)(de)于齊(qi)諾(nuo)爾公(gong)(gong)(gong)(gong)(gong)(gong)司(si)(si)、阿維(wei)斯塔·波拉里(li)特(te)公(gong)(gong)(gong)(gong)(gong)(gong)司(si)(si)、阿塞(sai)里(li)諾(nuo)克(ke)斯公(gong)(gong)(gong)(gong)(gong)(gong)司(si)(si)等(deng)(deng)競爭對手相(xiang)抗衡,該(gai)公(gong)(gong)(gong)(gong)(gong)(gong)司(si)(si)采(cai)取了一(yi)系列策略,如擴大產(chan)(chan)(chan)能、采(cai)用先進(jin)技術、注重(zhong)產(chan)(chan)(chan)品結(jie)構重(zhong)組,改善為(wei)用戶(hu)服(fu)務(wu)。在(zai)(zai)(zai)意大利的(de)(de)(de)(de)、90%控股的(de)(de)(de)(de)子公(gong)(gong)(gong)(gong)(gong)(gong)司(si)(si)AST是一(yi)個(ge)(ge)具有冶煉、連鑄、熱軋(ya)(ya)和冷軋(ya)(ya)等(deng)(deng)全(quan)流(liu)程的(de)(de)(de)(de)不(bu)銹(xiu)(xiu)(xiu)(xiu)鋼(gang)和電工(gong)鋼(gang)生(sheng)產(chan)(chan)(chan)企(qi)業,第二座(zuo)AOD裝置已(yi)投產(chan)(chan)(chan),一(yi)臺薄板坯連鑄機也已(yi)投入運行,第五套森(sen)(sen)(sen)吉米爾軋(ya)(ya)機和一(yi)條新的(de)(de)(de)(de)光亮退火(huo)線相(xiang)繼開工(gong)投產(chan)(chan)(chan)。這些都使AST公(gong)(gong)(gong)(gong)(gong)(gong)司(si)(si)特(te)爾尼廠不(bu)銹(xiu)(xiu)(xiu)(xiu)鋼(gang)的(de)(de)(de)(de)產(chan)(chan)(chan)能明顯提(ti)高,不(bu)銹(xiu)(xiu)(xiu)(xiu)鋼(gang)熱軋(ya)(ya)帶鋼(gang)的(de)(de)(de)(de)年(nian)(nian)(nian)(nian)產(chan)(chan)(chan)能力(li)將(jiang)增(zeng)至65萬(wan)噸,預計2003年(nian)(nian)(nian)(nian)總產(chan)(chan)(chan)量(liang)(liang)(liang)可達(da)150萬(wan)噸。此外(wai),克(ke)虜伯·蒂(di)森(sen)(sen)(sen)不(bu)銹(xiu)(xiu)(xiu)(xiu)鋼(gang)公(gong)(gong)(gong)(gong)(gong)(gong)司(si)(si)正(zheng)在(zai)(zai)(zai)謀求在(zai)(zai)(zai)美國建廠或尋求新的(de)(de)(de)(de)合(he)作伙伴,以求與(yu)(yu)該(gai)公(gong)(gong)(gong)(gong)(gong)(gong)司(si)(si)的(de)(de)(de)(de)子公(gong)(gong)(gong)(gong)(gong)(gong)司(si)(si)墨(mo)西哥(ge)不(bu)銹(xiu)(xiu)(xiu)(xiu)鋼(gang)公(gong)(gong)(gong)(gong)(gong)(gong)司(si)(si)一(yi)起保(bao)證整(zheng)個(ge)(ge)北(bei)美自由貿易區(qu)的(de)(de)(de)(de)供(gong)應。目前在(zai)(zai)(zai)北(bei)美自由貿易區(qu)的(de)(de)(de)(de)銷(xiao)售(shou)量(liang)(liang)(liang)占(zhan)克(ke)虜伯·蒂(di)森(sen)(sen)(sen)不(bu)銹(xiu)(xiu)(xiu)(xiu)鋼(gang)公(gong)(gong)(gong)(gong)(gong)(gong)司(si)(si)總銷(xiao)售(shou)量(liang)(liang)(liang)的(de)(de)(de)(de)15%.墨(mo)西哥(ge)不(bu)銹(xiu)(xiu)(xiu)(xiu)鋼(gang)公(gong)(gong)(gong)(gong)(gong)(gong)司(si)(si)冷軋(ya)(ya)廠的(de)(de)(de)(de)年(nian)(nian)(nian)(nian)產(chan)(chan)(chan)能力(li)為(wei)22萬(wan)噸,現正(zheng)以一(yi)半(ban)以上的(de)(de)(de)(de)產(chan)(chan)(chan)量(liang)(liang)(liang)供(gong)應美國。北(bei)美是一(yi)個(ge)(ge)極(ji)具吸引(yin)力(li)的(de)(de)(de)(de)市場(chang)。克(ke)虜伯·蒂(di)森(sen)(sen)(sen)不(bu)銹(xiu)(xiu)(xiu)(xiu)鋼(gang)公(gong)(gong)(gong)(gong)(gong)(gong)司(si)(si)以同(tong)樣(yang)的(de)(de)(de)(de)策略三年(nian)(nian)(nian)(nian)前進(jin)入中國,與(yu)(yu)寶鋼(gang)集(ji)團上海浦(pu)東鋼(gang)鐵(tie)公(gong)(gong)(gong)(gong)(gong)(gong)司(si)(si)成立(li)了上海克(ke)虜伯不(bu)銹(xiu)(xiu)(xiu)(xiu)鋼(gang)合(he)資公(gong)(gong)(gong)(gong)(gong)(gong)司(si)(si),該(gai)公(gong)(gong)(gong)(gong)(gong)(gong)司(si)(si)是一(yi)座(zuo)年(nian)(nian)(nian)(nian)產(chan)(chan)(chan)50萬(wan)噸粗鋼(gang)的(de)(de)(de)(de)全(quan)流(liu)程的(de)(de)(de)(de)不(bu)銹(xiu)(xiu)(xiu)(xiu)鋼(gang)扁(bian)平(ping)材(cai)生(sheng)產(chan)(chan)(chan)企(qi)業,2001年(nian)(nian)(nian)(nian)11月一(yi)期工(gong)程投產(chan)(chan)(chan),年(nian)(nian)(nian)(nian)產(chan)(chan)(chan)光亮板能力(li)達(da)7.2萬(wan)噸。

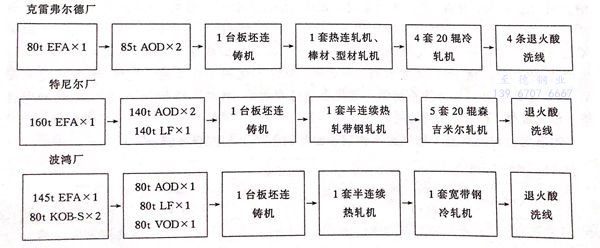

克(ke)虜伯·蒂(di)森不銹鋼公司(si)的不銹鋼生產工藝流程如下:

其工藝流程的特(te)點可概括(kuo)為:

①. 從熔煉、連鑄(zhu)、熱(re)軋(ya)到(dao)冷軋(ya)全部工序均(jun)一體化,采用二步法(fa)和三步法(fa)煉鋼工藝對提高鋼材質量、降低成本起到(dao)關鍵(jian)作用。

②. 在(zai)特(te)尼爾廠新建的(de)(de)CSP型薄板坯連鑄(zhu)(zhu)機(ji)(ji),先期鑄(zhu)(zhu)出的(de)(de)板坯厚度(du)為60mm,然后用(yong)現有的(de)(de)熱(re)軋(ya)機(ji)(ji)在(zai)線軋(ya)制(zhi)成厚度(du)為2~6mm的(de)(de)熱(re)帶。另外該廠新建一條(tiao)退火(huo)和酸洗生產(chan)線,將調整軋(ya)制(zhi)和退火(huo)酸洗能力之間的(de)(de)不平衡,從而使冷軋(ya)帶材(cai)產(chan)量提(ti)高到8萬噸/年左右,這是同類生產(chan)線中(zhong)最(zui)高的(de)(de)。

③. 正考慮(lv)在克雷(lei)弗爾德廠新建第五座冷(leng)軋廠,多出的15萬噸/年生(sheng)產能(neng)力將(jiang)與當地新的退火和酸洗線相匹配。

④. 克(ke)虜(lu)伯·蒂森(sen)不銹鋼公司(si)努力(li)向(xiang)每位客戶提(ti)供符(fu)合客戶要求的(de)規(gui)格(ge)、尺(chi)寸(cun)、數(shu)量(liang)的(de)優質扁平材(cai)。在(zai)克(ke)雷(lei)弗爾(er)德新(xin)建歐洲最大的(de)不銹鋼服務(wu)中(zhong)心,對(dui)不銹鋼進行精(jing)整深加工。

克虜伯·蒂森不銹鋼公司的主要產品有奧氏(shi)體不(bu)銹鋼熱軋酸洗板和各種表面狀態的冷軋板卷,鐵素體不(bu)銹鋼酸洗熱軋板卷和厚規格的奧氏體不銹鋼冷軋板卷。