這里所指的不銹鋼管材加工成型,包括管材彎曲、旋壓、擴徑、減徑和拉拔等,并且不銹(xiu)鋼(gang)管的材質僅僅限于標準的300和400系列不銹鋼。

1. 成(cheng)型管(guan)材的選擇

成(cheng)型之(zhi)前,首先要考慮的因素之(zhi)一是對何種形式不銹鋼管(guan)材進行成(cheng)型。也就是說(shuo),是對無縫鋼管(guan),還是焊接(jie)鋼管(guan)成(cheng)型;是對拉拔鋼管(guan),還是熱處理的鋼管(guan)成(cheng)型。

一般來說,幾乎每一種標準牌號的不銹鋼都可用一種或幾種常見的加工方法制作不銹鋼管。這些加工方法有棒材穿孔、管坯擠壓和冷軋帶鋼焊接等加工方法。然而,各種生產方法的原材料利用率是各不相同的,而且這些方法或許可以互用,或許根本不能互用。然而,經過對每一種不銹鋼的分析,可以肯定地說,至少已經有三種以上的方法可以用來加工成型鋼管。至于每一種方法是如何成功地加工出不銹鋼管,則是一個不同的工藝問題。

因此,可(ke)以肯(ken)定,采(cai)用一種(zhong)加工(gong)方(fang)式,使(shi)用一種(zhong)成型(xing)(xing)設備(bei)是不(bu)可(ke)能加工(gong)生(sheng)(sheng)(sheng)(sheng)產(chan)出(chu)所有材質、類(lei)(lei)型(xing)(xing)或(huo)尺寸的不(bu)銹鋼管(guan),也(ye)不(bu)可(ke)能同時(shi)加工(gong)生(sheng)(sheng)(sheng)(sheng)產(chan)各(ge)種(zhong)性能的無縫或(huo)焊(han)接鋼管(guan)。所以,生(sheng)(sheng)(sheng)(sheng)產(chan)費用的估算(suan)不(bu)應該基于可(ke)能生(sheng)(sheng)(sheng)(sheng)產(chan)的不(bu)銹鋼管(guan)產(chan)品類(lei)(lei)型(xing)(xing)上(shang),還必須考慮某種(zhong)鋼管(guan)生(sheng)(sheng)(sheng)(sheng)產(chan)設備(bei)的生(sheng)(sheng)(sheng)(sheng)產(chan)能力(li)和經(jing)濟(ji)效益。

易切(qie)削(xue)牌(pai)號的不(bu)(bu)(bu)(bu)銹鋼(gang)(gang)(gang)(gang)可(ke)(ke)(ke)以加(jia)(jia)工(gong)(gong)成(cheng)無(wu)縫(feng)鋼(gang)(gang)(gang)(gang)管(guan)(guan)(guan)(guan)(guan),它(ta)在尺寸方面采用(yong)擠壓的方法比穿孔(kong)方法更容易達到。另(ling)一(yi)方面,這些(xie)鋼(gang)(gang)(gang)(gang)種(zhong)由(you)于含有非(fei)金(jin)屬夾雜物,是(shi)(shi)絕對不(bu)(bu)(bu)(bu)適宜采用(yong)焊(han)接(jie)方式加(jia)(jia)工(gong)(gong)生(sheng)(sheng)產(chan)(chan)(chan)鋼(gang)(gang)(gang)(gang)管(guan)(guan)(guan)(guan)(guan)的。具有強的空淬性,并有較高碳含量的馬氏體鋼(gang)(gang)(gang)(gang) 20Cr13(420)和108Cr17(400C)型,可(ke)(ke)(ke)用(yong)來生(sheng)(sheng)產(chan)(chan)(chan)無(wu)縫(feng)鋼(gang)(gang)(gang)(gang)管(guan)(guan)(guan)(guan)(guan),但(dan)(dan)不(bu)(bu)(bu)(bu)能(neng)(neng)(neng)(neng)(neng)生(sheng)(sheng)產(chan)(chan)(chan)焊(han)接(jie)鋼(gang)(gang)(gang)(gang),根據(ju)生(sheng)(sheng)產(chan)(chan)(chan)廠的生(sheng)(sheng)產(chan)(chan)(chan)能(neng)(neng)(neng)(neng)(neng)力,10Cr17(430)鋼(gang)(gang)(gang)(gang)既有可(ke)(ke)(ke)能(neng)(neng)(neng)(neng)(neng)加(jia)(jia)工(gong)(gong)成(cheng)無(wu)縫(feng)鋼(gang)(gang)(gang)(gang)管(guan)(guan)(guan)(guan)(guan),也(ye)可(ke)(ke)(ke)能(neng)(neng)(neng)(neng)(neng)加(jia)(jia)工(gong)(gong)為(wei)焊(han)接(jie)鋼(gang)(gang)(gang)(gang)管(guan)(guan)(guan)(guan)(guan),或者(zhe)兩(liang)者(zhe)都不(bu)(bu)(bu)(bu)可(ke)(ke)(ke)能(neng)(neng)(neng)(neng)(neng)。有些(xie)工(gong)(gong)廠不(bu)(bu)(bu)(bu)愿意加(jia)(jia)工(gong)(gong)生(sheng)(sheng)產(chan)(chan)(chan)400鋼(gang)(gang)(gang)(gang)焊(han)接(jie)鋼(gang)(gang)(gang)(gang)管(guan)(guan)(guan)(guan)(guan)。所以,440鋼(gang)(gang)(gang)(gang)可(ke)(ke)(ke)生(sheng)(sheng)產(chan)(chan)(chan)無(wu)縫(feng)鋼(gang)(gang)(gang)(gang)管(guan)(guan)(guan)(guan)(guan),但(dan)(dan)不(bu)(bu)(bu)(bu)能(neng)(neng)(neng)(neng)(neng)加(jia)(jia)工(gong)(gong)成(cheng)焊(han)接(jie)鋼(gang)(gang)(gang)(gang)管(guan)(guan)(guan)(guan)(guan),這是(shi)(shi)因(yin)為(wei)10Cr17(430)和16Cr25N(446)鋼(gang)(gang)(gang)(gang)在焊(han)接(jie)區域,有較大(da)晶粒和脆化(hua)的趨勢(shi)。一(yi)般來說,普通的18-8期(qi)及其穩(wen)定化(hua)處理(li)后的不(bu)(bu)(bu)(bu)銹鋼(gang)(gang)(gang)(gang)都可(ke)(ke)(ke)以用(yong)來加(jia)(jia)工(gong)(gong)制(zhi)作(zuo)無(wu)縫(feng)鋼(gang)(gang)(gang)(gang)管(guan)(guan)(guan)(guan)(guan)或焊(han)接(jie)鋼(gang)(gang)(gang)(gang)管(guan)(guan)(guan)(guan)(guan)。像沉淀硬化(hua)鋼(gang)(gang)(gang)(gang)這樣(yang)的許多非(fei)標(biao)準鋼(gang)(gang)(gang)(gang)種(zhong),由(you)于不(bu)(bu)(bu)(bu)是(shi)(shi)單相合(he)金(jin),因(yin)此它(ta)們往(wang)往(wang)不(bu)(bu)(bu)(bu)可(ke)(ke)(ke)能(neng)(neng)(neng)(neng)(neng)進行穿孔(kong),就是(shi)(shi)擠壓成(cheng)型也(ye)有一(yi)些(xie)困難(nan),但(dan)(dan)可(ke)(ke)(ke)用(yong)焊(han)接(jie)方法順利地加(jia)(jia)工(gong)(gong)制(zhi)作(zuo)不(bu)(bu)(bu)(bu)銹鋼(gang)(gang)(gang)(gang)管(guan)(guan)(guan)(guan)(guan)。當鋼(gang)(gang)(gang)(gang)管(guan)(guan)(guan)(guan)(guan)的外徑很大(da)或者(zhe)管(guan)(guan)(guan)(guan)(guan)壁較厚(hou)時(shi),是(shi)(shi)不(bu)(bu)(bu)(bu)能(neng)(neng)(neng)(neng)(neng)用(yong)焊(han)接(jie)方法來加(jia)(jia)工(gong)(gong)生(sheng)(sheng)產(chan)(chan)(chan)的。

2. 不(bu)銹鋼鋼管的回火效應

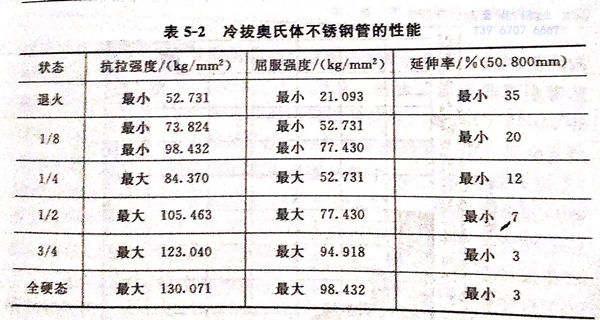

由于(yu)(yu)(yu)(yu)冷加(jia)工(gong)(gong)(gong)引起的(de)加(jia)工(gong)(gong)(gong)硬(ying)化(hua)(hua)(hua),就意味著(zhu)(zhu)在隨后(hou)成型(xing)(xing)(xing)加(jia)工(gong)(gong)(gong)要進(jin)(jin)(jin)行(xing)回(hui)火處(chu)理。所以(yi)(yi)回(hui)火對成型(xing)(xing)(xing)加(jia)工(gong)(gong)(gong)方(fang)法和(he)費用(yong)有(you)著(zhu)(zhu)直接(jie)的(de)影響(xiang)。人們(men)(men)都(dou)知道,當金屬接(jie)近或(huo)低于(yu)(yu)(yu)(yu)室溫變形時(shi)(shi),就會(hui)產(chan)生(sheng)硬(ying)化(hua)(hua)(hua),使(shi)金屬材(cai)料的(de)強度(du)和(he)硬(ying)度(du)增高。實際上(shang),并不(bu)是(shi)(shi)所有(you)的(de)不(bu)銹(xiu)鋼(gang)(gang)(gang)管(guan)都(dou)能(neng)進(jin)(jin)(jin)行(xing)所希望的(de)成型(xing)(xing)(xing)加(jia)工(gong)(gong)(gong)的(de)。如鐵(tie)素(su)體(ti)400系列不(bu)銹(xiu)鋼(gang)(gang)(gang)管(guan),在冷加(jia)工(gong)(gong)(gong)時(shi)(shi),只能(neng)有(you)較(jiao)小的(de)變形量(liang),否則就會(hui)發生(sheng)突然(ran)(ran)破壞或(huo)開裂。像10Cr17(430)和(he)16Cr25N(446)不(bu)銹(xiu)鋼(gang)(gang)(gang)自身就有(you)缺口敏感性(xing),因此它們(men)(men)的(de)供貨(huo)狀(zhuang)(zhuang)態(tai)應為退火狀(zhuang)(zhuang)態(tai)。當必須對它們(men)(men)進(jin)(jin)(jin)行(xing)成型(xing)(xing)(xing)加(jia)工(gong)(gong)(gong)時(shi)(shi),必須進(jin)(jin)(jin)行(xing)回(hui)火處(chu)理。硬(ying)化(hua)(hua)(hua)馬(ma)氏(shi)體(ti)鋼(gang)(gang)(gang)也是(shi)(shi)以(yi)(yi)退火狀(zhuang)(zhuang)態(tai)供貨(huo),否則這(zhe)些鋼(gang)(gang)(gang)種(zhong)就是(shi)(shi)以(yi)(yi)常(chang)化(hua)(hua)(hua)加(jia)固(gu)化(hua)(hua)(hua),或(huo)者以(yi)(yi)淬(cui)火加(jia)固(gu)化(hua)(hua)(hua)狀(zhuang)(zhuang)態(tai)交貨(huo)。然(ran)(ran)而奧氏(shi)體(ti)不(bu)銹(xiu)鋼(gang)(gang)(gang)管(guan),它們(men)(men)能(neng)在較(jiao)大(da)的(de)冷加(jia)工(gong)(gong)(gong)硬(ying)度(du)范圍供貨(huo)。表5-2列出(chu)了(le)與(yu)奧氏(shi)體(ti)300系列不(bu)銹(xiu)鋼(gang)(gang)(gang)各(ge)種(zhong)回(hui)火有(you)關的(de)機(ji)械性(xing)能(neng),并不(bu)是(shi)(shi)所有(you)尺寸和(he)鋼(gang)(gang)(gang)種(zhong)的(de)奧氏(shi)體(ti)不(bu)銹(xiu)鋼(gang)(gang)(gang)管(guan)在回(hui)火后(hou)都(dou)可以(yi)(yi)成型(xing)(xing)(xing)加(jia)工(gong)(gong)(gong)。然(ran)(ran)而,含合金量(liang)較(jiao)少的(de)12Cr17Mn6Ni5N(201)、12Cr1Mn9Ni5(202)、12Cr17Ni7(301)、12Cr19Ni9(302)和(he)06Cr19Nil0(304)鋼(gang)(gang)(gang)種(zhong)非常(chang)適合于(yu)(yu)(yu)(yu)冷拔(ba);對于(yu)(yu)(yu)(yu)合金含量(liang)較(jiao)高、冷加(jia)工(gong)(gong)(gong)硬(ying)化(hua)(hua)(hua)速率低的(de)鋼(gang)(gang)(gang)種(zhong),并沒有(you)廣(guang)泛地用(yong)于(yu)(yu)(yu)(yu)生(sheng)產(chan)大(da)于(yu)(yu)(yu)(yu)1/2冷作硬(ying)化(hua)(hua)(hua)狀(zhuang)(zhuang)態(tai)的(de)回(hui)火產(chan)品。10Cr18Ni12(305)、06Cr17Ni12Mo2(316)、06Cr19Ni13Mo3(317)和(he)20Cr25Ni20(310)鋼(gang)(gang)(gang)屬于(yu)(yu)(yu)(yu)后(hou)一類(lei)。隨著(zhu)(zhu)鎳(nie)含量(liang)的(de)增加(jia),加(jia)工(gong)(gong)(gong)硬(ying)化(hua)(hua)(hua)的(de)趨(qu)勢(shi)就會(hui)減輕。

冷拔奧氏體不(bu)銹鋼管的性能,見(jian)表5-2。

應該提(ti)及的是,一些非標準(zhun)鉻-錳奧氏體不銹鋼(gang),明顯地(di)擴大(da)了冷拔鋼(gang)管(guan)的加工范圍。

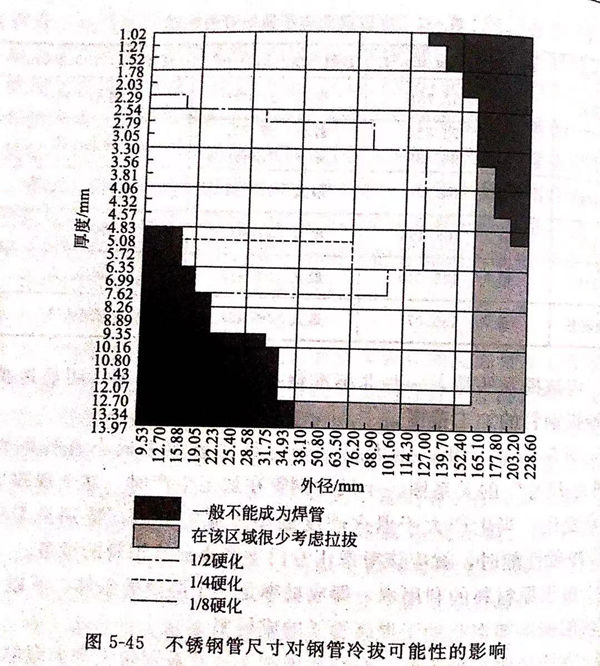

圖5-45表(biao)示出,由(you)大尺(chi)(chi)寸(cun)(cun)鋼(gang)管經冷拔(ba)加工成小(xiao)(xiao)直徑鋼(gang)管的“回火(huo)-尺(chi)(chi)寸(cun)(cun)”的關系圖。小(xiao)(xiao)尺(chi)(chi)寸(cun)(cun)鋼(gang)管在加工生(sheng)(sheng)產(chan)時(shi),這個規律可(ke)能(neng)有(you)點變化。當生(sheng)(sheng)產(chan)大于(yu)退火(huo)硬度(du)的小(xiao)(xiao)尺(chi)(chi)寸(cun)(cun)鋼(gang)管時(shi),特別(bie)是希望有(you)1/2冷硬性能(neng)時(shi),就應該考慮用專門生(sheng)(sheng)產(chan)小(xiao)(xiao)尺(chi)(chi)寸(cun)(cun)不(bu)銹鋼(gang)管的設備。

由于原材(cai)料的利用(yong)率,即成材(cai)率是一(yi)個必(bi)要(yao)的條件(jian),所以希望上述的基本(ben)知識有助于提高管子(zi)的成材(cai)率。

在冷拔不銹鋼(gang)管加工時,必須考慮加工尺寸對鋼管生產的限制。由于加工的限制,潤滑劑性能和上述分析的內在因素,只有某些尺寸的不銹鋼管在各種回火狀態下是可以進行冷拔加工的。