現階段腐蝕實驗是探究金(jin)屬(shu)腐(fu)蝕以及防護的主要手段,通過腐蝕實驗可以探究金屬發生腐蝕的規律及機理、檢查并篩選金屬材料的材質、估算金屬材料的使用壽命、分析金屬材料腐蝕事故的原因以及驗證防腐蝕的效果等。目前探究金屬腐蝕以及防護的方式有多種,如表面分析法、失重法以及電化學法。因為大部分金屬產生的腐蝕都是電化學腐蝕,而腐蝕過程中發生的電化學反應為電化學腐蝕的本質,所以金屬/電解質界面(雙電層)的電化學性質被大量使用于探究金屬腐蝕發生的規律、腐蝕產生的機理等方面。因此,在現有的研究金屬腐蝕與防護的方法中,電化學方法是一種較為重要的方法。腐蝕電化學法能夠按照腐蝕金屬電極特點的不同而分為以下三種類型:①. 電化學動力研究方法,指利用控制極化電流及電極電位來測定腐蝕體系中的熱力學參數;②. 獨用的腐蝕電化學測量跟研究法,指按照金屬電化學腐蝕的獨特性建立相應的電化學測量跟研究方法;③. 通過模擬裝置來探究具有獨特腐蝕形態的電化學測試技術,如模擬SSRT裂紋尖端的裝置、研究縫隙腐蝕的閉塞電池等。這幾種方法中最基礎的為電化學動力法。

電(dian)(dian)(dian)(dian)(dian)極(ji)電(dian)(dian)(dian)(dian)(dian)位以(yi)及電(dian)(dian)(dian)(dian)(dian)流(liu)密度為(wei)腐(fu)蝕電(dian)(dian)(dian)(dian)(dian)化(hua)學實驗所(suo)要(yao)獲得的重要(yao)參數,其中(zhong)電(dian)(dian)(dian)(dian)(dian)極(ji)電(dian)(dian)(dian)(dian)(dian)位表示電(dian)(dian)(dian)(dian)(dian)解液-金屬界(jie)面的特性和結(jie)構(gou);電(dian)(dian)(dian)(dian)(dian)流(liu)密度表示金屬材料表面上單位面積內(nei)電(dian)(dian)(dian)(dian)(dian)化(hua)學反(fan)應進行(xing)的快慢。絕大多(duo)數電(dian)(dian)(dian)(dian)(dian)化(hua)學測(ce)試都是(shi)測(ce)定電(dian)(dian)(dian)(dian)(dian)極(ji)電(dian)(dian)(dian)(dian)(dian)位跟電(dian)(dian)(dian)(dian)(dian)流(liu)密度這(zhe)兩者間(jian)的關(guan)聯。

與其他電(dian)化(hua)學(xue)過程(如電(dian)鍍、電(dian)解及化(hua)學(xue)電(dian)源等)相比(bi),金屬(shu)電(dian)化(hua)學(xue)腐蝕測量過程的對象是金屬(shu)電(dian)極,該過程有如下特點:

1. 金屬發生腐蝕的(de)整個(ge)腐蝕體系(xi)由數個(ge)電(dian)極(ji)反應耦合而成,同時在(zai)整個(ge)電(dian)極(ji)表面上也(ye)發生著(zhu)數個(ge)電(dian)極(ji)反應,所以(yi)與只具有(you)一(yi)個(ge)電(dian)極(ji)反應的(de)電(dian)極(ji)系(xi)統相比,其在(zai)分析和處(chu)理腐蝕電(dian)化學實驗結(jie)果(guo)上有(you)著(zhu)一(yi)定特別之處(chu)。

2. 電(dian)極(ji)金屬材料發生陽極(ji)溶解反(fan)應(ying),即(ji)腐蝕金屬自(zi)身參與的(de)反(fan)應(ying)是電(dian)極(ji)系(xi)統中(zhong)電(dian)極(ji)反(fan)應(ying)中(zhong)的(de)一種(zhong)。

3. 測量(liang)過程中不可以(yi)只(zhi)探(tan)究整(zheng)個電(dian)極(ji)(ji)表(biao)(biao)面(mian)(mian)(mian)(mian)總的(de)電(dian)化學行為(wei),因為(wei)電(dian)極(ji)(ji)表(biao)(biao)面(mian)(mian)(mian)(mian)表(biao)(biao)現為(wei)多層(ceng)結構,金(jin)屬電(dian)極(ji)(ji)上有(you)著腐蝕產物銹層(ceng)、腐蝕孔及表(biao)(biao)面(mian)(mian)(mian)(mian)膜,導致電(dian)極(ji)(ji)表(biao)(biao)面(mian)(mian)(mian)(mian)具有(you)不光滑(hua)的(de)特點(dian),容(rong)易發生各(ge)種形式的(de)局部腐蝕,所以(yi)有(you)必要發展如微區(qu)電(dian)化學測試之(zhi)類的(de)能夠表(biao)(biao)征電(dian)極(ji)(ji)表(biao)(biao)面(mian)(mian)(mian)(mian)不均(jun)勻性的(de)研究方法(fa)。

4. 腐(fu)蝕金屬的電極反應相對于其他一些電化(hua)學(xue)過程(cheng)而(er)言比(bi)較(jiao)緩慢。

此外,腐蝕電(dian)(dian)化學測試方法為(wei)原位(wei)技術,能夠(gou)比較(jiao)真實(shi)(shi)(shi)(shi)地反應金屬電(dian)(dian)極表面發生(sheng)的(de)實(shi)(shi)(shi)(shi)際腐蝕,擁有(you)較(jiao)強的(de)靈敏度、操(cao)作簡單容易(yi)實(shi)(shi)(shi)(shi)施且(qie)實(shi)(shi)(shi)(shi)時性好的(de)優點。電(dian)(dian)化學實(shi)(shi)(shi)(shi)驗常用的(de)方法有(you)極化曲線、交流阻抗(kang)及電(dian)(dian)位(wei)掃(sao)描等。

極(ji)(ji)化(hua)(hua)曲(qu)線的(de)測(ce)量有利于研究電(dian)(dian)(dian)極(ji)(ji)過(guo)程的(de)影(ying)響(xiang)因素和機理。眾所(suo)周(zhou)知,當我(wo)們探究可(ke)(ke)逆電(dian)(dian)(dian)池的(de)反(fan)應(ying)時電(dian)(dian)(dian)極(ji)(ji)上基本上是不存(cun)在(zai)(zai)電(dian)(dian)(dian)流(liu)(liu)(liu)的(de),各個電(dian)(dian)(dian)極(ji)(ji)的(de)反(fan)應(ying)基本都在(zai)(zai)平衡(heng)狀(zhuang)態下發生,所(suo)以該反(fan)應(ying)為可(ke)(ke)逆的(de)。但是一(yi)旦(dan)存(cun)在(zai)(zai)電(dian)(dian)(dian)流(liu)(liu)(liu)通過(guo),電(dian)(dian)(dian)極(ji)(ji)原本的(de)平衡(heng)狀(zhuang)態就被打(da)破(po),進而導(dao)致電(dian)(dian)(dian)極(ji)(ji)電(dian)(dian)(dian)位(wei)偏離原本的(de)平衡(heng)電(dian)(dian)(dian)位(wei)值(zhi)(zhi),導(dao)致電(dian)(dian)(dian)極(ji)(ji)反(fan)應(ying)處(chu)于一(yi)種(zhong)不可(ke)(ke)逆的(de)狀(zhuang)態,不可(ke)(ke)逆程度隨(sui)著電(dian)(dian)(dian)極(ji)(ji)電(dian)(dian)(dian)流(liu)(liu)(liu)密度的(de)升高而增強,即所(suo)謂的(de)電(dian)(dian)(dian)極(ji)(ji)極(ji)(ji)化(hua)(hua)就是指由于電(dian)(dian)(dian)流(liu)(liu)(liu)通過(guo)電(dian)(dian)(dian)極(ji)(ji)而導(dao)致電(dian)(dian)(dian)位(wei)偏離平衡(heng)值(zhi)(zhi)的(de)一(yi)種(zhong)現狀(zhuang),極(ji)(ji)化(hua)(hua)曲(qu)線即表示電(dian)(dian)(dian)極(ji)(ji)電(dian)(dian)(dian)位(wei)與電(dian)(dian)(dian)流(liu)(liu)(liu)密度兩者間的(de)關系(xi),其測(ce)試有以下幾種(zhong)方法。

a. 恒(heng)電位法(fa)

恒電(dian)(dian)位(wei)法(fa)(fa)即將被(bei)研究的(de)電(dian)(dian)極(ji)電(dian)(dian)位(wei)固定(ding)(ding)在不同的(de)電(dian)(dian)位(wei)上,然后測(ce)(ce)試(shi)對(dui)應(ying)電(dian)(dian)位(wei)下的(de)電(dian)(dian)極(ji)電(dian)(dian)流(liu)(liu)密(mi)度(du),在實際應(ying)用(yong)(yong)過程中使(shi)用(yong)(yong)較(jiao)為(wei)普遍(bian)的(de)是靜態(tai)法(fa)(fa)及動(dong)(dong)態(tai)法(fa)(fa)。所謂靜態(tai)法(fa)(fa)是指(zhi)控制電(dian)(dian)極(ji)電(dian)(dian)位(wei)為(wei)某一個(ge)特定(ding)(ding)值,測(ce)(ce)量相對(dui)應(ying)電(dian)(dian)位(wei)下的(de)電(dian)(dian)流(liu)(liu)密(mi)度(du),且(qie)依次測(ce)(ce)定(ding)(ding)整個(ge)電(dian)(dian)極(ji)電(dian)(dian)位(wei)下的(de)電(dian)(dian)流(liu)(liu)密(mi)度(du),從而得到整個(ge)極(ji)化(hua)曲(qu)(qu)線;其次動(dong)(dong)態(tai)法(fa)(fa)指(zhi)控制電(dian)(dian)極(ji)電(dian)(dian)位(wei)按(an)照(zhao)較(jiao)為(wei)緩慢(man)的(de)速(su)度(du)不停地變化(hua),并(bing)且(qie)測(ce)(ce)量相對(dui)應(ying)電(dian)(dian)位(wei)下的(de)電(dian)(dian)流(liu)(liu)值,瞬(shun)時電(dian)(dian)流(liu)(liu)與其相對(dui)應(ying)的(de)電(dian)(dian)位(wei)關(guan)系曲(qu)(qu)線即為(wei)極(ji)化(hua)曲(qu)(qu)線。這兩(liang)種方法(fa)(fa)中較(jiao)為(wei)廣泛使(shi)用(yong)(yong)的(de)是動(dong)(dong)態(tai)法(fa)(fa)測(ce)(ce)定(ding)(ding)極(ji)化(hua)曲(qu)(qu)線,該(gai)方法(fa)(fa)的(de)優點(dian)在于掃描速(su)度(du)可以控制、可以自動(dong)(dong)測(ce)(ce)量并(bing)繪制極(ji)化(hua)曲(qu)(qu)線,其測(ce)(ce)量的(de)結果有較(jiao)高的(de)重現性,對(dui)于那些(xie)需要比較(jiao)的(de)實驗(yan)該(gai)方法(fa)(fa)為(wei)首(shou)選(xuan)。

b. 恒電(dian)流法

恒電(dian)流法(fa)是指(zhi)固定電(dian)極(ji)(ji)體系的(de)電(dian)流密度為某一特定值(zhi),測(ce)(ce)(ce)定跟電(dian)流密度相(xiang)對應(ying)的(de)電(dian)極(ji)(ji)電(dian)位。恒電(dian)流法(fa)測(ce)(ce)(ce)量極(ji)(ji)化曲線在測(ce)(ce)(ce)定過程(cheng)中電(dian)極(ji)(ji)很難(nan)達到一個穩定的(de)狀態(tai),所以在實際測(ce)(ce)(ce)量過程(cheng)中一般當(dang)電(dian)位接(jie)近穩定的(de)時候即可(ke)以讀值(zhi)。

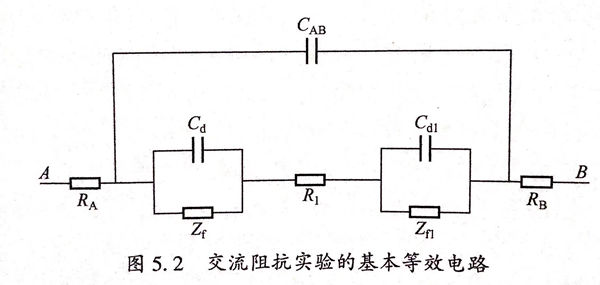

典型的動電位極化曲線如圖5.1所示。圖中Eb為金屬材料的點蝕電位,Ep為保護電位。同樣的實驗狀態下點蝕電位(Eb)值越大則意味著金屬產生點腐蝕的傾向越低;當幾種金屬材料的點蝕電位值相當,只有將點蝕電位和保護電位綜合考慮才能評價金屬的耐蝕能力,(Eb-Ep)差值越低表明材料鈍化膜修復能力越強,耐孔蝕性能越優,因而保護電位(Ep)和點蝕電位(Eb)是被用來表示金屬耐孔腐蝕能力大小的基本參數。在E>Eb的條件下,點蝕必然會發生,不但原來具有的蝕孔會長大而且還會產生新的蝕孔;在E<Ep的情況下不會發生點蝕,原來的孔蝕不會長大而且新的蝕孔也不會產生;在Ep<E<Eb條件下,孔蝕存在,原有的蝕孔會接著擴展并生長,但是新蝕孔不會產生。

電化學阻抗譜(Electrochemical Impedance Spectroscopy,EIS),在早期的電化學文獻中電化學阻抗又被稱為交流阻抗(Alternating Current impedance,AC im-pedance).電化學阻抗原先被用于電學中來探究線性電路網絡頻率響應特征,后來被用在電極上,進而成為電化學的研究方式。電化學阻抗譜的原理是指向電化學體系施予一頻率各異的小振幅交流電動勢,測定正弦波頻率(ω)的改變對該電動勢與電流信號比值產生的影響,即測定阻抗隨著正弦波頻率(ω)的變化,也可以通過測定阻抗的相位角Φ隨ω的變化來分析電極材料、腐蝕機理、導電材料、電極過程的動力學等方面的機理。采用小振幅的電信號既能夠防止給系統帶來較大的影響,同時又能夠讓擾動跟響應體系之間表現為近似線性的關系,進而讓測量的結果數學處理更容易。此外,電化學阻抗譜是通過測量過程中獲得的頻率比較寬的阻抗譜探究電極的,所以相對于另外一些電化學法其能夠得到電極界面結構和動力學信息。例如:通過阻抗譜形狀能夠探究金屬電極發生腐蝕的機理;探究金屬表面上保護膜的阻抗特征;對腐蝕金屬進行電化學阻抗測量可以獲得極化電阻(Rp);對腐蝕的金屬材料進行電化學阻抗譜測量,能夠了解動力學參數進而來研究金屬材料抗腐蝕能力的強弱等。因此,電化學阻抗譜成為近年來探究金屬發生腐蝕與采取相應防護措施的重要方式。

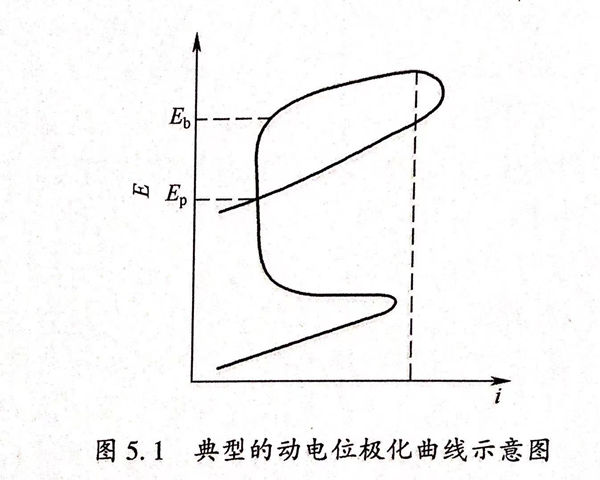

電(dian)(dian)(dian)(dian)(dian)(dian)(dian)化(hua)學(xue)(xue)(xue)阻(zu)(zu)抗(kang)(EIS)測試把電(dian)(dian)(dian)(dian)(dian)(dian)(dian)化(hua)學(xue)(xue)(xue)系統(tong)作(zuo)為(wei)一(yi)個等(deng)效電(dian)(dian)(dian)(dian)(dian)(dian)(dian)路(lu)(lu)(lu),交(jiao)(jiao)流阻(zu)(zu)抗(kang)實(shi)驗的(de)基本(ben)等(deng)效電(dian)(dian)(dian)(dian)(dian)(dian)(dian)路(lu)(lu)(lu)如圖5.2所示。該電(dian)(dian)(dian)(dian)(dian)(dian)(dian)路(lu)(lu)(lu)的(de)組(zu)成元(yuan)件(jian)(jian)有電(dian)(dian)(dian)(dian)(dian)(dian)(dian)阻(zu)(zu)(R:金屬(shu)材料對(dui)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)流的(de)阻(zu)(zu)攔功能(neng)(neng))、電(dian)(dian)(dian)(dian)(dian)(dian)(dian)感(L:于電(dian)(dian)(dian)(dian)(dian)(dian)(dian)路(lu)(lu)(lu)中對(dui)交(jiao)(jiao)流電(dian)(dian)(dian)(dian)(dian)(dian)(dian)的(de)阻(zu)(zu)礙(ai)功能(neng)(neng))及電(dian)(dian)(dian)(dian)(dian)(dian)(dian)容(C:電(dian)(dian)(dian)(dian)(dian)(dian)(dian)路(lu)(lu)(lu)中對(dui)交(jiao)(jiao)流電(dian)(dian)(dian)(dian)(dian)(dian)(dian)所引起的(de)阻(zu)(zu)礙(ai)作(zuo)用)等(deng),這些(xie)元(yuan)件(jian)(jian)按照串聯(lian)或(huo)者并(bing)聯(lian)的(de)方(fang)式組(zu)合起來形(xing)成一(yi)個等(deng)效電(dian)(dian)(dian)(dian)(dian)(dian)(dian)路(lu)(lu)(lu)。測量電(dian)(dian)(dian)(dian)(dian)(dian)(dian)化(hua)學(xue)(xue)(xue)阻(zu)(zu)抗(kang)能(neng)(neng)夠確定(ding)等(deng)效電(dian)(dian)(dian)(dian)(dian)(dian)(dian)路(lu)(lu)(lu)的(de)組(zu)成方(fang)式及各組(zu)成元(yuan)件(jian)(jian)的(de)值、通過這些(xie)元(yuan)件(jian)(jian)的(de)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)化(hua)學(xue)(xue)(xue)含(han)義就(jiu)可以分析電(dian)(dian)(dian)(dian)(dian)(dian)(dian)化(hua)學(xue)(xue)(xue)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)極過程的(de)性質和電(dian)(dian)(dian)(dian)(dian)(dian)(dian)化(hua)學(xue)(xue)(xue)系統(tong)的(de)結構(gou)。