大部分常用鎳鉻系奧氏體不銹鋼自高溫奧氏體狀態冷至室溫獲得的奧氏體基體組織都是亞穩定的,當繼續冷卻到室溫以下更低的溫度,或者經受冷變形,其中的一部分或大部分奧氏體會發生馬氏體轉變,變成馬氏體組織。不銹鋼中馬氏體有兩種形態:體心立方的a'馬氏體,呈鐵磁性;六方結構的ε馬氏體,為非鐵磁性。由于ε馬氏體總是與a'馬氏體伴隨而出現,有人認為ε馬氏體是γ→a'過程中的一種過渡相,也有人認為ε馬氏體是一種獨立相。

馬氏體轉(zhuan)變(bian)(bian)受鋼的化(hua)學成分、溫度(du)、冷變(bian)(bian)形量及變(bian)(bian)形速率(lv)的影響。

曾對(dui)不同(tong)成(cheng)分的(de)Fe-Mn-Cr-Ni合(he)金(jin)(jin)的(de)馬氏(shi)體相(xiang)(xiang)(xiang)(xiang)(xiang)變(bian)(bian)(bian)(bian)進行過研究(含(han)0.03%C、0.01%~0.03%Si、0.006%~0.019%N、0.012%~0.10%Al):含(han)20%Mn的(de)Fe-Mn合(he)金(jin)(jin)自(zi)1050℃水(shui)(shui)冷(leng)(leng)(leng)(leng)至(zhi)(zhi)室溫(wen),發(fa)生(sheng)(sheng)(sheng)γ→E轉(zhuan)變(bian)(bian)(bian)(bian),相(xiang)(xiang)(xiang)(xiang)(xiang)約(yue)(yue)為(wei)(wei)(wei)(wei)40%,再(zai)冷(leng)(leng)(leng)(leng)卻至(zhi)(zhi)-196℃,y相(xiang)(xiang)(xiang)(xiang)(xiang)幾乎(hu)全(quan)部轉(zhuan)變(bian)(bian)(bian)(bian)為(wei)(wei)(wei)(wei)ε相(xiang)(xiang)(xiang)(xiang)(xiang),只生(sheng)(sheng)(sheng)成(cheng)少量(liang)(liang)的(de)α'相(xiang)(xiang)(xiang)(xiang)(xiang)。成(cheng)分為(wei)(wei)(wei)(wei)Fe-5%Mn-15%Cr-9%Ni合(he)金(jin)(jin)自(zi)1050℃水(shui)(shui)冷(leng)(leng)(leng)(leng)至(zhi)(zhi)室溫(wen),10min后(hou)冷(leng)(leng)(leng)(leng)至(zhi)(zhi)-196℃,不發(fa)生(sheng)(sheng)(sheng)馬氏(shi)體相(xiang)(xiang)(xiang)(xiang)(xiang)變(bian)(bian)(bian)(bian),仍為(wei)(wei)(wei)(wei)100%的(de)y相(xiang)(xiang)(xiang)(xiang)(xiang);冷(leng)(leng)(leng)(leng)至(zhi)(zhi)室溫(wen),再(zai)在(zai)(zai)20℃下施(shi)以40%冷(leng)(leng)(leng)(leng)變(bian)(bian)(bian)(bian)形(xing),將發(fa)生(sheng)(sheng)(sheng)γ→ε+α'的(de)轉(zhuan)變(bian)(bian)(bian)(bian),轉(zhuan)變(bian)(bian)(bian)(bian)量(liang)(liang)約(yue)(yue)為(wei)(wei)(wei)(wei)20%,其中約(yue)(yue)2/3為(wei)(wei)(wei)(wei)ε相(xiang)(xiang)(xiang)(xiang)(xiang),1/3為(wei)(wei)(wei)(wei)α'相(xiang)(xiang)(xiang)(xiang)(xiang);如(ru)果自(zi)1050℃水(shui)(shui)冷(leng)(leng)(leng)(leng)至(zhi)(zhi)室溫(wen)后(hou),再(zai)在(zai)(zai)-196℃下施(shi)以40%的(de)冷(leng)(leng)(leng)(leng)變(bian)(bian)(bian)(bian)形(xing),發(fa)生(sheng)(sheng)(sheng)γ→e+α'的(de)轉(zhuan)變(bian)(bian)(bian)(bian),轉(zhuan)變(bian)(bian)(bian)(bian)量(liang)(liang)近90%,其中約(yue)(yue)1/4為(wei)(wei)(wei)(wei)ε相(xiang)(xiang)(xiang)(xiang)(xiang),3/4為(wei)(wei)(wei)(wei)a'相(xiang)(xiang)(xiang)(xiang)(xiang)。成(cheng)分為(wei)(wei)(wei)(wei)Fe-20%Cr-12%Ni的(de)合(he)金(jin)(jin)自(zi)1050℃水(shui)(shui)冷(leng)(leng)(leng)(leng),10min后(hou)冷(leng)(leng)(leng)(leng)至(zhi)(zhi)-196℃,不發(fa)生(sheng)(sheng)(sheng)馬氏(shi)體相(xiang)(xiang)(xiang)(xiang)(xiang)變(bian)(bian)(bian)(bian),冷(leng)(leng)(leng)(leng)至(zhi)(zhi)室溫(wen)在(zai)(zai)20℃下施(shi)以40%的(de)冷(leng)(leng)(leng)(leng)變(bian)(bian)(bian)(bian)形(xing),僅發(fa)生(sheng)(sheng)(sheng)γ→E轉(zhuan)變(bian)(bian)(bian)(bian),相(xiang)(xiang)(xiang)(xiang)(xiang)約(yue)(yue)為(wei)(wei)(wei)(wei)10%;如(ru)果冷(leng)(leng)(leng)(leng)至(zhi)(zhi)室溫(wen)后(hou)再(zai)在(zai)(zai)-196℃下施(shi)以40%的(de)冷(leng)(leng)(leng)(leng)變(bian)(bian)(bian)(bian)形(xing),將發(fa)生(sheng)(sheng)(sheng)γ→ε+α轉(zhuan)變(bian)(bian)(bian)(bian),轉(zhuan)變(bian)(bian)(bian)(bian)量(liang)(liang)約(yue)(yue)為(wei)(wei)(wei)(wei)55%,15%為(wei)(wei)(wei)(wei)ε相(xiang)(xiang)(xiang)(xiang)(xiang),40%為(wei)(wei)(wei)(wei)α'相(xiang)(xiang)(xiang)(xiang)(xiang)。

對(dui)于奧氏(shi)體(ti)不銹鋼的(de)(de)(de)馬氏(shi)體(ti)轉變的(de)(de)(de)臨(lin)界溫度M3,已建立(li)起若干Ms,點(a')與合金成分關系的(de)(de)(de)經驗(yan)公式,下面是其中的(de)(de)(de)一個表(biao)達(da)式:

上面(mian)兩個公式說明,奧氏(shi)體不(bu)銹鋼中合(he)金元(yuan)素含量越高,馬(ma)氏(shi)體點就越低,馬(ma)氏(shi)體轉(zhuan)變就越不(bu)容易發生(sheng)。

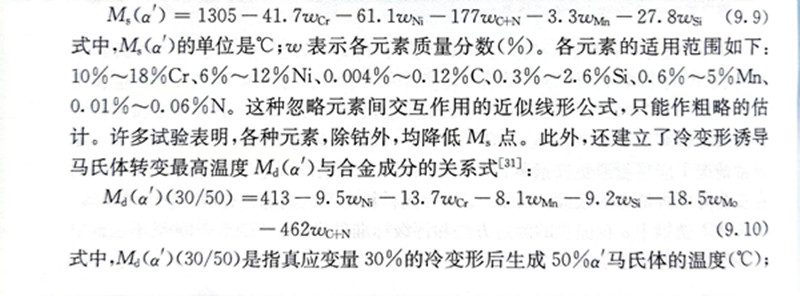

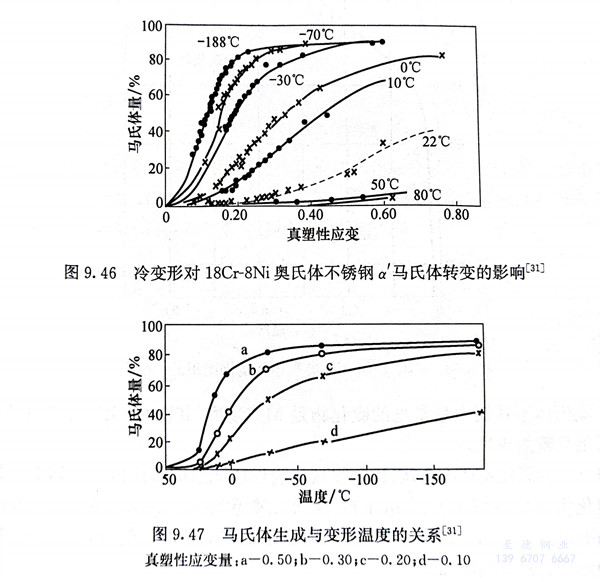

在18Cr-8Ni奧氏體不銹鋼中,α'馬氏體形成量隨冷變形量加大和變形溫度降低而增多,如圖9.46和圖9.47所示。可以看出,在每一變形溫度下,α'馬氏體含量隨冷變形量加大而增長到一定數值后將趨于飽和。隨變形溫度的降低,在同樣變形量的條件下,α'馬氏體的生成量增加,其增加也有一個飽和值,亦即無論采取什么措施,不可能完全轉變為馬氏體。這種奧氏體穩定化受多種因素影響,除合金成分和晶粒度等內在因素外,還有奧氏體化溫度、冷卻速率等外界因素。

變形速率對馬(ma)氏(shi)(shi)體轉變的影響主要是變形發(fa)熱導致材(cai)料溫(wen)度(du)上(shang)升的作用,即變形速率越(yue)高(gao),材(cai)料溫(wen)度(du)也越(yue)高(gao),因而α'馬(ma)氏(shi)(shi)體的生成量也越(yue)少。