在埋弧焊焊接過程中,維持電弧穩定燃燒,以及保持焊接參數基本不變是保證焊接接頭質量的基本要求。對此可通過以下兩種方法來實現。

1. 焊絲的(de)送進按預選定的(de)速度等速進入焊接區

工(gong)作(zuo)(zuo)原(yuan)理是(shi)采(cai)用(yong)機械(xie)方法(更換變(bian)速(su)齒輪)來調(diao)速(su)。依靠電弧(hu)(hu)(hu)的(de)(de)自身調(diao)節作(zuo)(zuo)用(yong)來維持弧(hu)(hu)(hu)長相對穩定。當(dang)焊(han)接電弧(hu)(hu)(hu)受到外界干擾變(bian)長增加時(shi),下降(jiang)外特性電源供(gong)給的(de)(de)焊(han)接電流減小(xiao),焊(han)絲熔(rong)化(hua)速(su)度(du)減緩,電弧(hu)(hu)(hu)便會(hui)由長變(bian)短(duan),趨(qu)(qu)向(xiang)給定值(zhi);反之,電弧(hu)(hu)(hu)變(bian)短(duan)時(shi),焊(han)接電流增大,焊(han)絲熔(rong)化(hua)加快,弧(hu)(hu)(hu)長又由短(duan)變(bian)長,趨(qu)(qu)向(xiang)給定值(zhi)。按(an)這個(ge)工(gong)作(zuo)(zuo)原(yuan)理制造的(de)(de)等速(su)送絲埋弧(hu)(hu)(hu)焊(han)設備有(you)MZ1-1000、MZ2-1500和(he)MZ3-500等型號,焊(han)接電流可采(cai)用(yong)交、直(zhi)電源。

2. 焊絲(si)的送進速度按電(dian)(dian)弧電(dian)(dian)壓的高低(di)自動均勻調節

電(dian)(dian)(dian)弧(hu)(hu)(hu)電(dian)(dian)(dian)壓調(diao)(diao)(diao)節原理是利(li)用電(dian)(dian)(dian)弧(hu)(hu)(hu)電(dian)(dian)(dian)壓作為反饋(kui)(kui)信號,經過控制調(diao)(diao)(diao)節系(xi)統改變(bian)送絲(si)(si)速度(du)(du)(du)而保持(chi)弧(hu)(hu)(hu)長(chang)(chang)相(xiang)對不變(bian)。當電(dian)(dian)(dian)弧(hu)(hu)(hu)受外界干擾變(bian)長(chang)(chang),電(dian)(dian)(dian)弧(hu)(hu)(hu)電(dian)(dian)(dian)壓升高時(shi),控制調(diao)(diao)(diao)節系(xi)統接到電(dian)(dian)(dian)壓反饋(kui)(kui)信號后將(jiang)送絲(si)(si)速度(du)(du)(du)調(diao)(diao)(diao)快(kuai),弧(hu)(hu)(hu)長(chang)(chang)由(you)長(chang)(chang)變(bian)短,趨向(xiang)穩定(ding)值;當電(dian)(dian)(dian)弧(hu)(hu)(hu)長(chang)(chang)度(du)(du)(du)變(bian)短,電(dian)(dian)(dian)弧(hu)(hu)(hu)電(dian)(dian)(dian)壓下(xia)降時(shi),將(jiang)送絲(si)(si)速度(du)(du)(du)調(diao)(diao)(diao)慢,弧(hu)(hu)(hu)長(chang)(chang)增長(chang)(chang)趨向(xiang)給定(ding)值。這種(zhong)埋弧(hu)(hu)(hu)焊(han)機的(de)控制系(xi)統稍復雜,具體型號有MZ-1000和MZ-1-1000等型號。焊(han)接電(dian)(dian)(dian)流可(ke)采用交、直流電(dian)(dian)(dian)源。

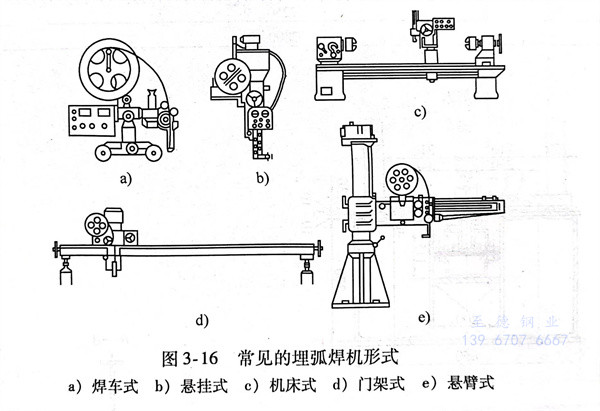

按工(gong)作需要,埋弧焊機常見(jian)的構造(zao)形式(shi)有焊車式(shi)、懸(xuan)(xuan)掛(gua)式(shi)、機床式(shi)、懸(xuan)(xuan)臂(bei)式(shi)和門架式(shi)等,如圖3-16所示。