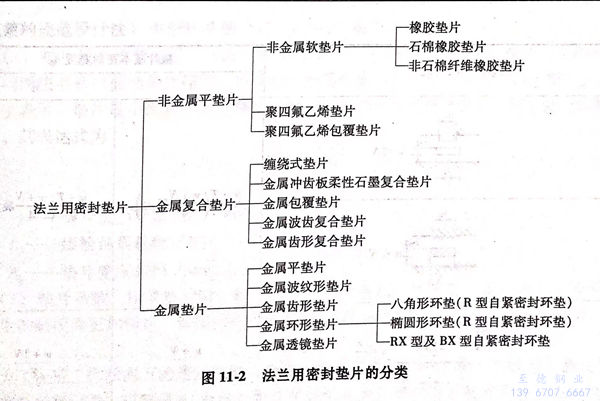

不銹鋼法蘭墊片的一般結構包括密封元件本體、內環、外環、表面層、增強層和抗黏結處理層等6部分。不銹鋼法蘭墊片的一般型式如圖11-1所示。

密(mi)(mi)封(feng)元(yuan)件(jian)本體(ti)(ti)2是(shi)(shi)阻止泄漏的(de)(de)關鍵部分。常(chang)用(yong)(yong)(yong)的(de)(de)材(cai)(cai)(cai)料(liao)(liao)為(wei)非(fei)金(jin)(jin)屬(shu)材(cai)(cai)(cai)料(liao)(liao),如(ru)(ru)柔(rou)性石墨、聚四(si)氟乙烯(xi)、纖(xian)維增(zeng)(zeng)(zeng)強(qiang)橡膠(jiao)基復合(he)(he)板(ban)等(deng)(deng)。此外,密(mi)(mi)封(feng)元(yuan)件(jian)本體(ti)(ti)材(cai)(cai)(cai)料(liao)(liao)也(ye)(ye)可(ke)以(yi)是(shi)(shi)剛(gang)性或柔(rou)性的(de)(de)金(jin)(jin)屬(shu),通(tong)常(chang)用(yong)(yong)(yong)于壓力和溫度較(jiao)高的(de)(de)場合(he)(he)。對于非(fei)金(jin)(jin)屬(shu)材(cai)(cai)(cai)料(liao)(liao)常(chang)通(tong)過(guo)金(jin)(jin)屬(shu)材(cai)(cai)(cai)料(liao)(liao)予以(yi)增(zeng)(zeng)(zeng)強(qiang),同(tong)時也(ye)(ye)方(fang)便了石墨等(deng)(deng)易破(po)碎(sui)材(cai)(cai)(cai)料(liao)(liao)的(de)(de)密(mi)(mi)封(feng)元(yuan)件(jian)的(de)(de)制造(zao)加(jia)工(gong)。增(zeng)(zeng)(zeng)強(qiang)材(cai)(cai)(cai)料(liao)(liao)也(ye)(ye)可(ke)以(yi)是(shi)(shi)金(jin)(jin)屬(shu)薄(bo)板(ban)或絲網,金(jin)(jin)屬(shu)薄(bo)板(ban)常(chang)采用(yong)(yong)(yong)沖刺孔(kong)的(de)(de)方(fang)式以(yi)提高增(zeng)(zeng)(zeng)強(qiang)效果和增(zeng)(zeng)(zeng)加(jia)彈性,并通(tong)過(guo)黏結(jie)(jie)劑和(或)輥壓將(jiang)它們貼合(he)(he)在一起。密(mi)(mi)封(feng)元(yuan)件(jian)也(ye)(ye)可(ke)以(yi)設(she)一表面(mian)(mian)層(ceng)4或抗黏結(jie)(jie)處理層(ceng)6來增(zeng)(zeng)(zeng)加(jia)密(mi)(mi)封(feng)效果和防止與法蘭密(mi)(mi)封(feng)面(mian)(mian)黏結(jie)(jie)。表面(mian)(mian)層(ceng)材(cai)(cai)(cai)料(liao)(liao)可(ke)以(yi)是(shi)(shi)聚四(si)氟乙烯(xi)或屈(qu)服強(qiang)度低(di)的(de)(de)金(jin)(jin)屬(shu)材(cai)(cai)(cai)料(liao)(liao)(如(ru)(ru)金(jin)(jin)、黃銅、軟鋼(gang)、鎳、蒙(meng)乃(nai)爾(er)合(he)(he)金(jin)(jin)等(deng)(deng)),也(ye)(ye)可(ke)以(yi)采用(yong)(yong)(yong)表面(mian)(mian)鍍層(ceng)、如(ru)(ru)鉛、錫、聚四(si)氟乙烯(xi)、金(jin)(jin)、銀等(deng)(deng)。密(mi)(mi)封(feng)元(yuan)件(jian)還可(ke)以(yi)用(yong)(yong)(yong)聚四(si)氟乙烯(xi)或金(jin)(jin)屬(shu)保(bao)護套包覆,其(qi)作用(yong)(yong)(yong)是(shi)(shi)使內芯(xin)材(cai)(cai)(cai)料(liao)(liao)免受被(bei)密(mi)(mi)封(feng)流體(ti)(ti)的(de)(de)化學侵蝕(shi),同(tong)時又(you)保(bao)持(chi)了內芯(xin)材(cai)(cai)(cai)料(liao)(liao)的(de)(de)彈性,如(ru)(ru)各種包覆結(jie)(jie)構形式的(de)(de)墊片。

外(wai)環3的作用(yong)是幫助密封元(yuan)件安裝時對中,從而防(fang)止密封元(yuan)件過分(fen)壓縮而破壞(huai),加固墊(dian)(dian)片(pian)(pian)本(ben)體、防(fang)止不(bu)(bu)銹鋼法蘭(lan)墊(dian)(dian)片(pian)(pian)吹出和(he)減少法蘭(lan)轉動等(deng)。外(wai)環材料為實心(xin)金屬(shu),因其(qi)不(bu)(bu)與流體介(jie)質接觸(chu),不(bu)(bu)要求(qiu)耐介(jie)質腐(fu)蝕,故常常采用(yong)碳(tan)鋼制(zhi)成。外(wai)環也可(ke)以(yi)與密封元(yuan)件制(zhi)成一體,例如金屬(shu)齒(chi)形墊(dian)(dian)片(pian)(pian)、波齒(chi)復合墊(dian)(dian)片(pian)(pian)等(deng)。

內環(huan)1是用(yong)來防(fang)止密封元件(jian)(jian)本體(ti)(ti)因(yin)剛性(xing)不足發生(sheng)向內屈曲;填(tian)補密封件(jian)(jian)與容器或管道法(fa)蘭密封面之(zhi)間(jian)的空(kong)隙(xi),以(yi)避免此空(kong)隙(xi)干擾流(liu)(liu)體(ti)(ti)的流(liu)(liu)動(dong),以(yi)及由此引起(qi)的流(liu)(liu)體(ti)(ti)對墊片的沖蝕,因(yin)為(wei)內環(huan)與流(liu)(liu)體(ti)(ti)接觸,所以(yi)其材料要能抵御(yu)被密封流(liu)(liu)體(ti)(ti)介質的腐蝕。

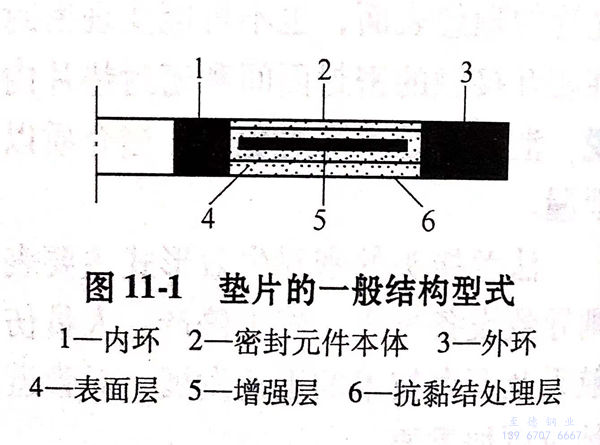

不銹(xiu)(xiu)鋼法蘭(lan)接頭中(zhong)所采用的墊(dian)片(pian)(pian),種類(lei)繁多,按其(qi)密封(feng)元件(jian)本體材料的不同(tong)和其(qi)結構特征(zheng)大致可分為非(fei)金屬(shu)平墊(dian)片(pian)(pian)、金屬(shu)復合墊(dian)片(pian)(pian)及金屬(shu)墊(dian)片(pian)(pian)三大類(lei),在各類(lei)中(zhong)又可細分成若干種。常用不銹(xiu)(xiu)鋼法蘭(lan)密封(feng)墊(dian)片(pian)(pian)的分類(lei)如圖11-2所示。