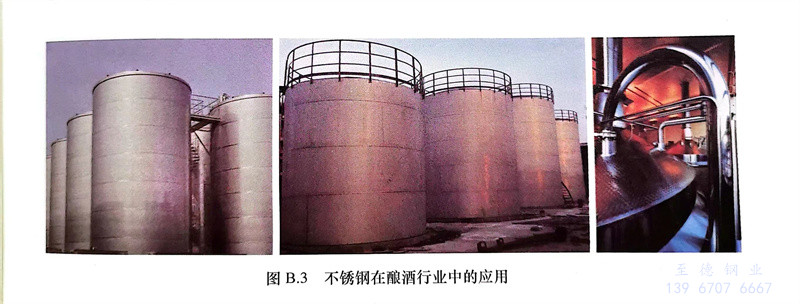

不銹鋼在食品生產、儲藏、運輸等設備制造中的應用很多,如啤酒、牛奶、酸奶、醋、醬油、飲料、方便面、掛面、餃子等食品生產線或生產設備。這些領域主要使用304不銹鋼(gang)和316不銹鋼,用戶可以根據使用環境或企業的綜合成本與壽命進行選擇。其使用的部位主要有輸送管道、料槽、容器、貯桶、搗碎機等。不銹鋼在釀酒行業中的應用如圖B.3所示。

1. 奧(ao)氏(shi)體不銹(xiu)鋼釀(niang)酒(jiu)設備選用

釀造酒業(ye)先進(jin)行(xing)曲(qu)的制作,其工藝以高(gao)溫曲(qu)為例,小麥→潤(run)料→磨碎→粗麥粉→攔曲(qu)料(加(jia)水)→踩(cai)曲(qu)→曲(qu)坯→堆(dui)積培養(yang)→成品曲(qu)→出房→儲存。踩(cai)曲(qu)采用踩(cai)曲(qu)機(不銹(xiu)鋼制造)進(jin)行(xing)。

白(bai)酒生產工(gong)藝流程:大曲(qu)→打碎(sui)→碾(nian)細→大曲(qu)粉→撒曲(qu)→入(ru)窖→出窖→堆放→發酵槽→配料(高(gao)粱粉碎(sui)+稻殼或高(gao)粱皮清(qing)蒸(zheng)(zheng))→裝(zhuang)甑→蒸(zheng)(zheng)糧蒸(zheng)(zheng)酒(+井水(shui))→出酒。儲酒有多種(zhong)裝(zhuang)置(zhi),如常用(yong)的不銹鋼大容器甑桶(tong)高(gao)1m,上(shang)口直徑(jing)1.7m,下(xia)口直徑(jing)1.5m,進氣壓力(li)0.15MPa,流酒溫度(du)35℃,甑內溫度(du)前期85~95℃,入(ru)庫(ku)酒精(jing)度(du)61°。

釀造(zao)啤酒行業:因微生物在(zai)(zai)啤酒里(li)迅速(su)繁殖,因此嚴格的衛生要求對(dui)現(xian)代釀酒業而言是(shi)絕對(dui)必要的。304和316不(bu)銹鋼(gang)廣泛(fan)用(yong)(yong)于儲罐、管道系統、閥(fa)門、泵和熱交換器(qi),因為它能(neng)夠(gou)被保持得干(gan)(gan)干(gan)(gan)凈凈。同(tong)樣不(bu)銹鋼(gang)啤酒桶(tong)結實、易消毒,并不(bu)會污染(ran)產品或使(shi)產品有(you)味(wei),長時(shi)間儲存(cun)葡萄酒而不(bu)會變質,在(zai)(zai)蒸汽(qi)空間里(li)能(neng)夠(gou)抵抗(kang)高酸性(xing)環境。不(bu)銹鋼(gang)桶(tong)易清潔,便于重復使(shi)用(yong)(yong)。年(nian)產2億升的企業的生產裝(zhuang)置約(yue)需(xu)要2500t不(bu)銹鋼(gang),包括釀造(zao)設(she)備(鍋、槽(cao)、容器(qi))、發酵(jiao)貯(zhu)酒(啤酒罐)、過濾(lv)器(qi)(容器(qi)、過濾(lv)機(ji)、板式冷(leng)卻器(qi))、包裝(zhuang)(鏈式包裝(zhuang)機(ji))、管閥(fa)等(deng)。

葡萄酒(jiu)(jiu)等(deng)(deng)生產(chan)設備(bei)也大量(liang)使用(yong)304和316不(bu)(bu)銹鋼,其中(zhong)304不(bu)(bu)銹鋼主(zhu)要用(yong)于(yu)容器(qi)(qi)桶、料槽、貯酒(jiu)(jiu)桶、發(fa)酵桶、過濾設備(bei)、搗碎機、壓力機、管件等(deng)(deng);316不(bu)(bu)銹鋼主(zhu)要用(yong)于(yu)蒸餾(liu)塔、冷凝器(qi)(qi)、分凝器(qi)(qi)、酒(jiu)(jiu)醋生產(chan)裝(zhuang)置(zhi),釀酒(jiu)(jiu)設備(bei)或配(pei)件用(yong)不(bu)(bu)銹鋼鋼種、主(zhu)要產(chan)品與生產(chan)企(qi)業如表B.3~表B.5所示。

2. 奧氏體不銹鋼乳制品設備鋼種選用(yong)

不銹鋼在乳制品行業主要用于加熱器、過濾器、冷卻槽、攪拌機等(圖B.4)。由于牛奶中要加鹽,因此牛奶會腐蝕更低合金化的不銹鋼,304L不(bu)銹(xiu)鋼滿足清洗/消毒過程的要求。乳品行業使用不銹鋼設備的主要產品、選材、鋼種、材料規格與生產企業等如表B.6和表B.7所示。

3. 奧氏體不(bu)銹鋼家禽加工(gong)設備(bei)選用

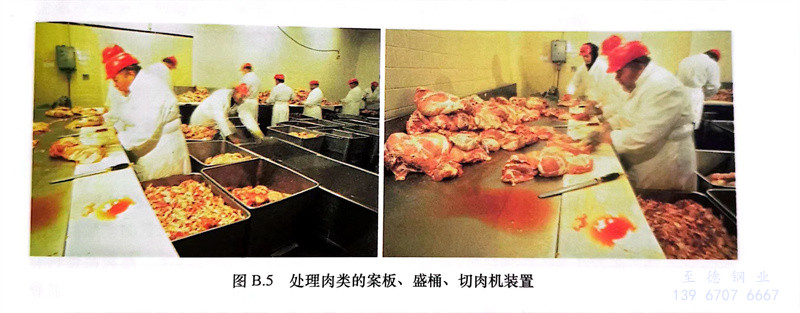

家禽加(jia)(jia)工設備(bei)大部分采用(yong)304不銹(xiu)鋼(gang),不論是(shi)(shi)家禽與加(jia)(jia)工設備(bei)接觸的部分還是(shi)(shi)設備(bei)框(kuang)架(jia)、馬達和齒輪箱(xiang)都采用(yong)了(le)不銹(xiu)鋼(gang)。

加(jia)工車(che)間(jian)的(de)操(cao)作環境非常潮(chao)濕,不(bu)僅在清(qing)(qing)潔(jie)操(cao)作中(zhong)是這樣,來自(zi)熱清(qing)(qing)潔(jie)液的(de)蒸汽會(hui)使(shi)人們很難看(kan)到車(che)間(jian)的(de)另一端。在清(qing)(qing)潔(jie)操(cao)作中(zhong),蒸汽凝結(jie)在設備(bei)的(de)其他部位,因(yin)此設備(bei)中(zhong)非加(jia)工部件,如門、門把手、鉸鏈、鏟子、欄(lan)桿甚(shen)至剪(jian)貼板也要使(shi)用(yong)不(bu)銹鋼(主要是304),如圖B.5所(suo)示。

4. 奧(ao)氏體不銹鋼冷藏集裝箱選用

不(bu)銹(xiu)鋼(gang)冷藏(zang)集裝箱由(you)(you)6部(bu)(bu)(bu)分組成(cheng)(cheng),分別為底架、側板(ban)(ban)(ban)(ban)(ban)(ban)(ban)、頂(ding)(ding)板(ban)(ban)(ban)(ban)(ban)(ban)(ban)、前框、后框和(he)門。底架由(you)(you)上部(bu)(bu)(bu)的T形鋁地板(ban)(ban)(ban)(ban)(ban)(ban)(ban)、下(xia)部(bu)(bu)(bu)的波紋底板(ban)(ban)(ban)(ban)(ban)(ban)(ban),兩側的下(xia)側梁部(bu)(bu)(bu)以及(ji)(ji)中間(jian)的發泡(pao)層組成(cheng)(cheng)。外(wai)側板(ban)(ban)(ban)(ban)(ban)(ban)(ban)由(you)(you)304不(bu)銹(xiu)鋼(gang)板(ban)(ban)(ban)(ban)(ban)(ban)(ban)壓制成(cheng)(cheng)波紋拼接而成(cheng)(cheng)。頂(ding)(ding)板(ban)(ban)(ban)(ban)(ban)(ban)(ban)由(you)(you)外(wai)頂(ding)(ding)板(ban)(ban)(ban)(ban)(ban)(ban)(ban)、內頂(ding)(ding)板(ban)(ban)(ban)(ban)(ban)(ban)(ban)等(deng)組成(cheng)(cheng),外(wai)頂(ding)(ding)板(ban)(ban)(ban)(ban)(ban)(ban)(ban)和(he)內頂(ding)(ding)板(ban)(ban)(ban)(ban)(ban)(ban)(ban)由(you)(you)304不(bu)銹(xiu)鋼(gang)板(ban)(ban)(ban)(ban)(ban)(ban)(ban)拼焊而成(cheng)(cheng)。門由(you)(you)外(wai)門板(ban)(ban)(ban)(ban)(ban)(ban)(ban)、內門板(ban)(ban)(ban)(ban)(ban)(ban)(ban)、中間(jian)發泡(pao)層及(ji)(ji)四周圍PVC等(deng)組成(cheng)(cheng),內門板(ban)(ban)(ban)(ban)(ban)(ban)(ban)與外(wai)門板(ban)(ban)(ban)(ban)(ban)(ban)(ban)由(you)(you)0.8mm厚度(du)304不(bu)銹(xiu)鋼(gang)組成(cheng)(cheng)。