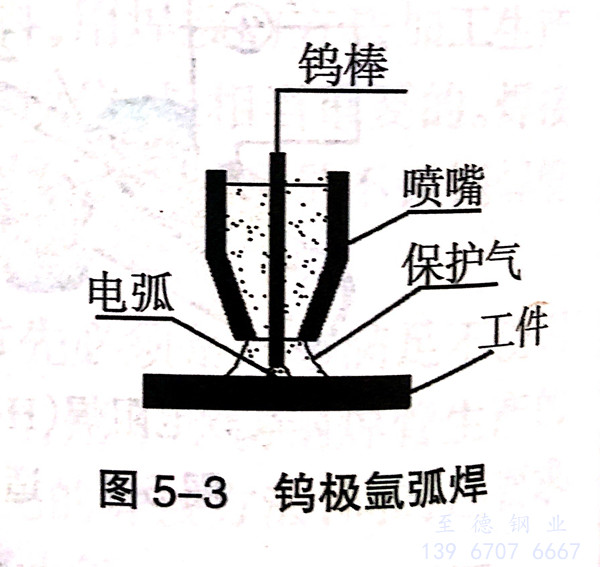

鎢極氬弧焊又叫做非熔化極氬弧焊,通常用TIG來表示,TIG是英文Tungsten Inert Gas Arc Welding的縮寫。鎢極氬弧焊是借助高熔點的金屬鎢作為一個電極,工件作為另一個電極,利用氬氣(Ar)作為保護氣體,并在鎢極與工件之間引燃電弧進行焊接,如圖5-3所示。

鎢(wu)(wu)極氬(ya)(ya)弧焊(han)(han)(han)(han)(han)焊(han)(han)(han)(han)(han)接(jie)(jie)時(shi),電(dian)極和電(dian)弧區及熔(rong)化金(jin)(jin)屬都處于氬(ya)(ya)氣(qi)保護(hu)之(zhi)中(zhong),使之(zhi)與(yu)空氣(qi)隔絕。當保護(hu)氣(qi)體(ti)采(cai)(cai)用氦氣(qi)時(shi)又稱氦弧焊(han)(han)(han)(han)(han),有時(shi)保護(hu)氣(qi)體(ti)采(cai)(cai)用按一定比(bi)例(li)混(hun)合(he)(he)(he)的混(hun)合(he)(he)(he)氣(qi)體(ti),如:氬(ya)(ya)氣(qi)和氦氣(qi)混(hun)合(he)(he)(he)、氬(ya)(ya)氣(qi)和氫氣(qi)混(hun)合(he)(he)(he)。鎢(wu)(wu)極氬(ya)(ya)弧焊(han)(han)(han)(han)(han)又可分為:直流鎢(wu)(wu)極氬(ya)(ya)弧焊(han)(han)(han)(han)(han)、交(jiao)流鎢(wu)(wu)極氬(ya)(ya)弧焊(han)(han)(han)(han)(han)和鎢(wu)(wu)極脈(mo)沖氬(ya)(ya)弧焊(han)(han)(han)(han)(han)等。鎢(wu)(wu)極氬(ya)(ya)弧焊(han)(han)(han)(han)(han)廣(guang)泛應用于不銹(xiu)鋼(gang)、鈦合(he)(he)(he)金(jin)(jin)、鋁(lv)合(he)(he)(he)金(jin)(jin)、活潑金(jin)(jin)屬和難熔(rong)金(jin)(jin)屬的焊(han)(han)(han)(han)(han)接(jie)(jie)。所以,在不銹(xiu)鋼(gang)焊(han)(han)(han)(han)(han)管(guan)(guan)、鈦合(he)(he)(he)金(jin)(jin)焊(han)(han)(han)(han)(han)管(guan)(guan)和鋁(lv)合(he)(he)(he)金(jin)(jin)焊(han)(han)(han)(han)(han)管(guan)(guan)生(sheng)產中(zhong)都廣(guang)泛地應用了鎢(wu)(wu)極氬(ya)(ya)弧焊(han)(han)(han)(han)(han)。

一、保護氣體

鎢極(ji)氬(ya)(ya)弧焊(han)常(chang)用(yong)的保(bao)護氣(qi)(qi)(qi)(qi)體(ti)(ti)有單一純氬(ya)(ya)氣(qi)(qi)(qi)(qi)和混合氣(qi)(qi)(qi)(qi)體(ti)(ti)(氬(ya)(ya)+氫氬(ya)(ya)+氦)。有關焊(han)接常(chang)用(yong)保(bao)護氣(qi)(qi)(qi)(qi)體(ti)(ti),請參(can)考(kao)第三章(zhang)《3.5.5焊(han)接用(yong)保(bao)護氣(qi)(qi)(qi)(qi)體(ti)(ti)》。

1. 氬氣

氬氣比空(kong)氣重25%,是一(yi)種惰性(xing)氣體,用(yong)做保(bao)護(hu)氣體,不與(yu)金屬起(qi)化學作用(yong),不溶解(jie)于金屬中,也不易漂浮散失,有利于保(bao)護(hu)作用(yong)。另(ling)外,氬氣的導熱系數小,而且是單(dan)元子氣體,高溫下不分解(jie)吸熱,所以(yi)在氬氣中燃燒(shao)的電(dian)(dian)弧熱量(liang)損失較(jiao)小。氬氣保(bao)護(hu)焊時,電(dian)(dian)弧一(yi)經引燃,燃燒(shao)就很穩定(ding)(ding)。在各類保(bao)護(hu)氣體中,氬弧的穩定(ding)(ding)性(xing)最好(hao),即使在低電(dian)(dian)弧電(dian)(dian)壓時也十分穩定(ding)(ding),一(yi)般氬弧焊電(dian)(dian)弧電(dian)(dian)壓僅8V~15V。

2. 氬(ya)氣、氫氣混合(he)氣體

在焊接(jie)保(bao)護氣(qi)體(ti)氬氣(qi)(Ar)中(zhong)加人適量的氫氣(qi)(H2),可提高(gao)(gao)電弧溫度,增加母材熱量輸入,從(cong)而提高(gao)(gao)焊接(jie)速度。

3. 氬氣、氦氣混合(he)氣體

在焊接保護氣體氬氣(Ar)中(zhong)加入(ru)適量的氦(He),也可(ke)以提高電弧溫(wen)度,增(zeng)加母(mu)材熱量輸入(ru),進而也能達到提高焊接速度的目的。

二、電(dian)極材料及其形狀

鎢(wu)(wu)(wu)極(ji)氬弧焊用的(de)(de)電極(ji)為(wei)鎢(wu)(wu)(wu)或氧(yang)(yang)化(hua)(hua)鎢(wu)(wu)(wu),其(qi)熔點高(gao)達3400℃,鎢(wu)(wu)(wu)的(de)(de)逸出功為(wei)4.5eV,發射電子能(neng)(neng)力強(qiang);氧(yang)(yang)化(hua)(hua)鎢(wu)(wu)(wu)的(de)(de)發射電子能(neng)(neng)力更強(qiang)。氧(yang)(yang)化(hua)(hua)鎢(wu)(wu)(wu)的(de)(de)制造(zao)工藝關鍵是氧(yang)(yang)化(hua)(hua)物(wu)與基體(ti)材料的(de)(de)均勻性(xing),這樣可提高(gao)電極(ji)的(de)(de)引(yin)弧性(xing)能(neng)(neng)和穩弧性(xing)能(neng)(neng)。目前國內外常(chang)用的(de)(de)鎢(wu)(wu)(wu)電極(ji)材料主要有純鎢(wu)(wu)(wu)、鈰鎢(wu)(wu)(wu)和釷(tu)鎢(wu)(wu)(wu)3種(zhong)。

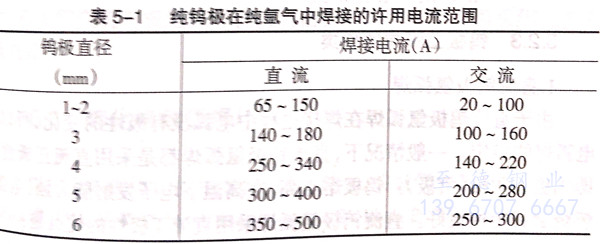

相同的(de)鎢(wu)(wu)(wu)電(dian)極(ji)(ji)直徑,采(cai)用(yong)不(bu)同的(de)極(ji)(ji)性,其載流能(neng)力相差很大,純鎢(wu)(wu)(wu)極(ji)(ji)在純氬氣(qi)中焊接的(de)許用(yong)電(dian)流范圍見表(biao)5-1。交流焊時,采(cai)用(yong)非對(dui)稱波(bo)形(xing)或對(dui)稱波(bo)形(xing),其載流能(neng)力也有差別。國外最常用(yong)的(de)是釷鎢(wu)(wu)(wu)極(ji)(ji),國內普遍采(cai)用(yong)鈰(shi)鎢(wu)(wu)(wu)極(ji)(ji),其引弧與穩弧性能(neng)都不(bu)亞于釷鎢(wu)(wu)(wu)極(ji)(ji)。

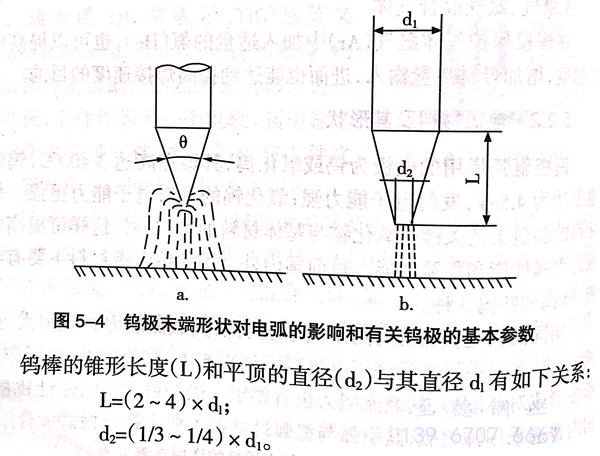

實踐證明,鎢(wu)極末(mo)端的(de)形(xing)狀對(dui)焊接許用(yong)電(dian)(dian)(dian)流(liu)大(da)(da)小和焊縫(feng)(feng)(feng)成(cheng)型(xing)有直接影響(xiang)(xiang)。一般在(zai)焊接薄板和焊接電(dian)(dian)(dian)流(liu)較(jiao)小時(shi)(shi),可用(yong)小直徑的(de)鎢(wu)極并將其磨成(cheng)尖錐(zhui)形(xing)(約20°),這樣(yang),電(dian)(dian)(dian)弧容易引燃(ran)且穩定(ding)。但(dan)在(zai)焊接電(dian)(dian)(dian)流(liu)較(jiao)大(da)(da)時(shi)(shi)仍用(yong)尖錐(zhui)角(jiao),會因電(dian)(dian)(dian)流(liu)密度過大(da)(da),而使尖錐(zhui)角(jiao)過熱(re)熔化并增(zeng)加(jia)燒損(sun);電(dian)(dian)(dian)弧斑點也(ye)會擴展到鎢(wu)極末(mo)端的(de)錐(zhui)面上,使弧柱明顯地擴散(san)而飄(piao)蕩不穩,影響(xiang)(xiang)焊接電(dian)(dian)(dian)流(liu)和焊縫(feng)(feng)(feng)成(cheng)型(xing)(圖5-4a).因此,在(zai)大(da)(da)電(dian)(dian)(dian)流(liu)焊接時(shi)(shi)要求鎢(wu)極磨成(cheng)鈍(dun)錐(zhui)角(jiao)(大(da)(da)于90°)或(huo)帶(dai)有平頂的(de)錐(zhui)形(xing)(圖5-4b),這樣(yang)可使電(dian)(dian)(dian)弧斑點穩定(ding),弧柱的(de)擴散(san)減小,對(dui)焊件加(jia)熱(re)集(ji)中(zhong),焊縫(feng)(feng)(feng)成(cheng)型(xing)均勻。

三、鎢極氬弧焊的種類

1. 直流鎢(wu)極氬(ya)弧焊(han)

由于直(zhi)流(liu)鎢(wu)(wu)極(ji)(ji)(ji)氬弧焊在焊接過程中電弧沒有極(ji)(ji)(ji)性的(de)變(bian)化,所(suo)以(yi),電弧燃燒穩定(ding)。一般(ban)情況(kuang)下(xia),直(zhi)流(liu)鎢(wu)(wu)極(ji)(ji)(ji)氬弧焊都是(shi)采(cai)用(yong)直(zhi)流(liu)正極(ji)(ji)(ji)性,即鎢(wu)(wu)極(ji)(ji)(ji)為陰(yin)極(ji)(ji)(ji)(負(fu)極(ji)(ji)(ji))。鎢(wu)(wu)極(ji)(ji)(ji)熔點(dian)(dian)高(gao),在高(gao)溫下(xia)電子發射能(neng)力強(qiang),電弧燃燒會(hui)穩定(ding)性更好。直(zhi)流(liu)鎢(wu)(wu)極(ji)(ji)(ji)氬弧焊采(cai)用(yong)直(zhi)流(liu)正極(ji)(ji)(ji)性的(de)優(you)點(dian)(dian)是(shi):

a. 工(gong)件(jian)為陽極(正極),工(gong)件(jian)接(jie)(jie)受(shou)電子轟擊放出的(de)全部動能和(he)位能(逸出功),會(hui)產生大量的(de)熱。因此,熔池深而窄,焊接(jie)(jie)效(xiao)率高,工(gong)件(jian)的(de)收(shou)縮和(he)變形都小。

b. 鎢極(ji)接受正離(li)子(zi)轟(hong)擊(ji)時(shi)放出的能(neng)量比較小,并且由(you)于鎢極(ji)在發射電(dian)子(zi)時(shi)需(xu)(xu)要付出大量的逸出功,鎢極(ji)產(chan)生(sheng)的熱量比較小,因而不易(yi)過熱。所以,對于同(tong)一(yi)焊(han)接電(dian)流(liu)(liu),可以采用直(zhi)徑較小的鎢棒。例如,同(tong)樣通過125A焊(han)接電(dian)流(liu)(liu)選(xuan)用Φ1.6mm的鎢極(ji)就(jiu)夠了,而直(zhi)流(liu)(liu)反極(ji)性時(shi)需(xu)(xu)用ф6mm的鎢極(ji)。

c. 鎢棒(bang)的熱(re)發射力(li)很強,當(dang)采用小直(zhi)徑(jing)鎢棒(bang)時,電(dian)流密度大(da),有利(li)于電(dian)弧(hu)穩(wen)定(ding),所以,電(dian)弧(hu)穩(wen)定(ding)性也比直(zhi)流反極性好。

總之,直流(liu)正極性(xing)優點較多(duo),焊接中(zhong)應盡可能采(cai)用直流(liu)正極性(xing)。

2. 脈沖(chong)鎢極氬弧(hu)焊

脈(mo)沖(chong)鎢(wu)極(ji)氬(ya)弧焊(han)(han)(han)焊(han)(han)(han)接(jie)(jie)時,平均焊(han)(han)(han)接(jie)(jie)電(dian)(dian)流是由(you)脈(mo)沖(chong)電(dian)(dian)流、基(ji)值電(dian)(dian)流、脈(mo)沖(chong)時間和(he)基(ji)值時間4個參數確定(ding)的(de)(de)。正確調節這4個電(dian)(dian)參數,可以增加(jia)熔(rong)深,降低熱影響(xiang)區寬度,提高(gao)焊(han)(han)(han)縫(feng)背面(mian)成型(xing)能(neng)力和(he)增加(jia)熔(rong)池(chi)的(de)(de)攪拌作(zuo)用(yong)(yong),是一種極(ji)好的(de)(de)焊(han)(han)(han)接(jie)(jie)方法。所(suo)以,脈(mo)沖(chong)鎢(wu)極(ji)氬(ya)弧焊(han)(han)(han)也廣泛地應用(yong)(yong)于不銹鋼(gang)焊(han)(han)(han)管領域,特別適(shi)用(yong)(yong)于薄(bo)壁焊(han)(han)(han)管的(de)(de)焊(han)(han)(han)接(jie)(jie)。

3. 交流(liu)鎢極氬弧焊

交(jiao)流(liu)(liu)鎢(wu)(wu)極(ji)(ji)氬(ya)弧(hu)焊(han)焊(han)接(jie)時,由于正(zheng)負兩半波的(de)(de)電弧(hu)電壓及再引(yin)燃電壓不同,導(dao)致焊(han)接(jie)電流(liu)(liu)不對稱(cheng),從而(er)產(chan)生直流(liu)(liu)分量(liang)。這既影響了焊(han)縫成型,又惡化(hua)了電源的(de)(de)工作條件。所以交(jiao)流(liu)(liu)鎢(wu)(wu)極(ji)(ji)氬(ya)弧(hu)焊(han)焊(han)接(jie)電源中(zhong)要設置引(yin)弧(hu)、穩弧(hu)和消除直流(liu)(liu)分量(liang)的(de)(de)裝置,一般在(zai)不銹鋼(gang)焊(han)管生產(chan)中(zhong),不使用交(jiao)流(liu)(liu)鎢(wu)(wu)極(ji)(ji)氬(ya)弧(hu)焊(han),但鋁、鋁合金(jin)焊(han)接(jie)管就必須采用交(jiao)流(liu)(liu)鎢(wu)(wu)極(ji)(ji)氬(ya)弧(hu)焊(han)。